Description

Overview

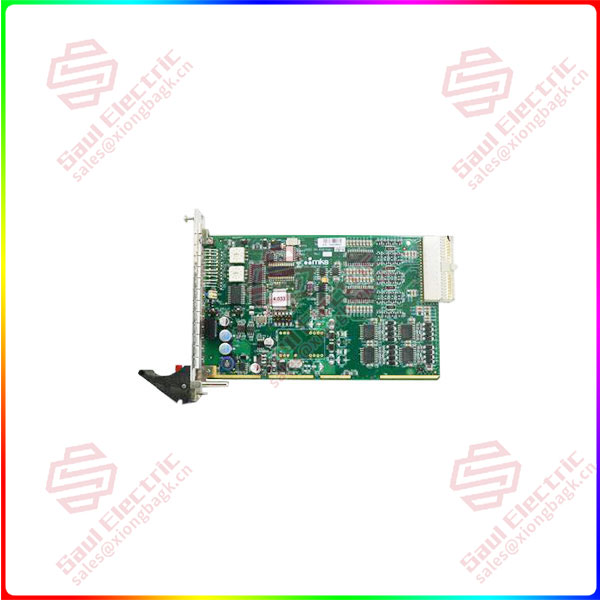

Essential details:0190-34055 AMAT Digital Quantity Control Board

CNC system and related automation products are mainly for CNC machine tools. Numerical control machine tool is a mechanical and electrical integration product formed by the penetration of new technology represented by numerical control system to the traditional machinery manufacturing industry: CNC machine tools equipped with CNC system greatly improve the precision, speed and efficiency of parts processing. This kind of CNC working machine is one of the important material bases of national industrial modernization.

The concept of numerical control (referred to as “numerical control” or “NC”) is to convert the requirements of the machined mechanical parts, such as shape, size and other information into numerical data command signals to be transmitted to the electronic control device, which controls the movement of the machine tool and processes the parts. In the traditional manual machining, these processes need to be manually operated machinery to achieve, it is difficult to meet the requirements of complex parts for processing, especially for multi-variety, small batch parts, processing efficiency is low, poor accuracy.

In 1952, the Massachusetts Institute of Technology and Parsons Company cooperated and invented the world’s first three-dimensional CNC milling machine. The control unit consists of more than 2,000 tubes, about the size of an average laboratory. The servo mechanism uses a small servo motor to change the Angle of the swash plate of the hydraulic motor to control the speed of the hydraulic motor. The interpolation device uses a pulse multiplier. The successful development of this NC machine tool marks the creation of NC technology and the beginning of a new, numerical control era in machinery manufacturing.

0190-34055

Superiority products 0190-34055 AMAT Digital Quantity Control Board

Application of software

At the Chicago Exhibition in 1970, the CNC system composed of minicomputers was first exhibited. Around the same time, Intel invented the microprocessor. In 1974, the United States, Japan and other countries have developed a microprocessor as the core of CNC, sometimes known as MNC. It uses the program in the computer memory to complete the function required by the numerical control. All or part of its control functions are realized by software, including decoding, tool compensation, speed processing, interpolation, position control, etc. The semiconductor memory store parts processing program can replace the punched parts paper tape program for processing, this program is easy to display, check, modify and edit, so it can reduce the hardware configuration of the system and improve the reliability of the system. The software control greatly increases the flexibility of the system and reduces the manufacturing cost of the system.

1 Year Warranty

1 Year Warranty