First mover empowerment

Activating Supply chain “synergies”

The pain points of low-carbon transformation of enterprises are often difficult to solve themselves, and they need to be empowered by “pioneers”. The pioneer is not only the leader of supply chain construction, but also the industry benchmark of sustainable development. And enablers need to be willing to take on the burden of driving upstream and downstream carbon reduction. Only in this way can mature carbon reduction concepts and advanced carbon reduction technologies, rich expert resources and comprehensive landing experience empower upstream and downstream enterprises and activate the “synergistic effect” of carbon reduction in the supply chain.

Shi Jia is such a “capable, willing” forerunner and enabler. We are not only a “double expert” in supply chain management and sustainable development, but also actively drive upstream and downstream enterprises to jointly reduce carbon and work together to promote the process of industrial carbon reduction.

With leading actions in supply chain construction, Shijia has been ranked on Gartner’s “Top 25 Global Supply Chains” list for eight consecutive years, rising to the top of the global ranking in 2023.

Of the 29 factories and logistics centers in China, 18 are smart factories and smart logistics centers.

In terms of sustainable development, Shijia has 65 “zero carbon factories” worldwide, 17 “zero carbon factories” in China, 15 “green factories” and 12 “carbon neutral” factories recognized by the Ministry of Industry and Information Technology.

Through the deployment of a variety of digital operation systems, the overall energy consumption of the supply chain in Shijia China was reduced by 13%.

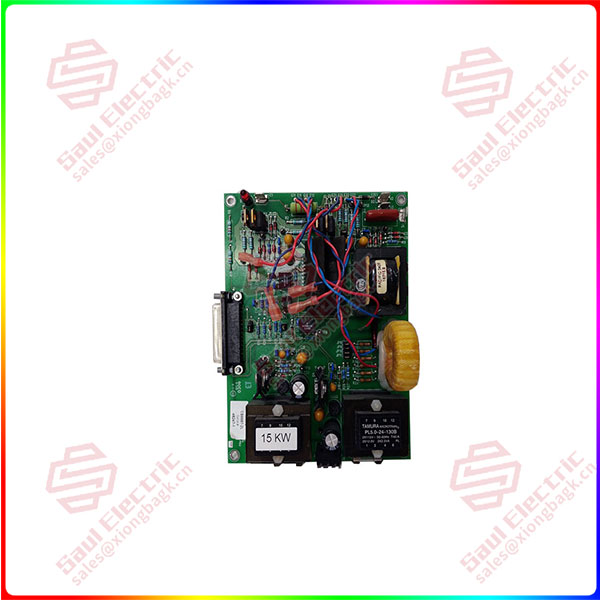

CB6687-2L

Schneider Electric Beijing Yizhuang factory

Shijia also offered a long-term commitment to addressing climate change:

To be carbon neutral in their own operations by 2025;

Achieve “zero carbon readiness” at the operational level by 2030;

Achieve carbon neutrality across the end-to-end value chain by 2040;

Achieve net zero carbon emissions across the end-to-end value chain by 2050.

At present, Shijia has built an end-to-end green supply chain covering green design, green procurement, green production, green delivery and green operation and maintenance. The Zero Carbon Initiative, launched in July 2021 for global suppliers, is an important practice to advance the end-to-end carbon reduction goal.

The Schneider Electric Supplier Zero Carbon Program aims to help the world’s top 1,000 suppliers reduce carbon emissions by 50% by 2025 by providing technical guidance and consulting services, including 230 core suppliers in China. In the past two years, Shijia has helped global suppliers reduce carbon emissions by an average of 20%, and it is worth mentioning that the carbon reduction results of Chinese suppliers are particularly significant, with an average carbon reduction of 21%.

1 Year Warranty

1 Year Warranty