Injection molding machine is widely used in the rubber and plastic industry and even some metal processing industries. Its working principle is that thermoplastic material or hot melt material is injected into the jet mechanism, high-speed injection filling mold, after high temperature or cooling and then forming. The rubber and plastic industry is one of the earliest industries to launch the national safety standard, and the danger of its equipment can be seen.

As a kind of equipment with high risk, the safety protection of injection molding machine is often taken out for science popularization. Previously, Pierci had briefly analyzed some standard requirements for the safety protection of the mold closing area of the injection molding machine, These are from standard ISO 20430 – Plastics and rubber machines – Injection moulding machines – Safety requirements, This standard covers all aspects of the safety requirements of an injection molding machine, and is definitely the “bible” for the safety application of injection molding machines.

ISO 20430 is a Class C standard for injection molding machines that sets out safety requirements for the design, construction and use of injection molding machines used in rubber and plastic processing.

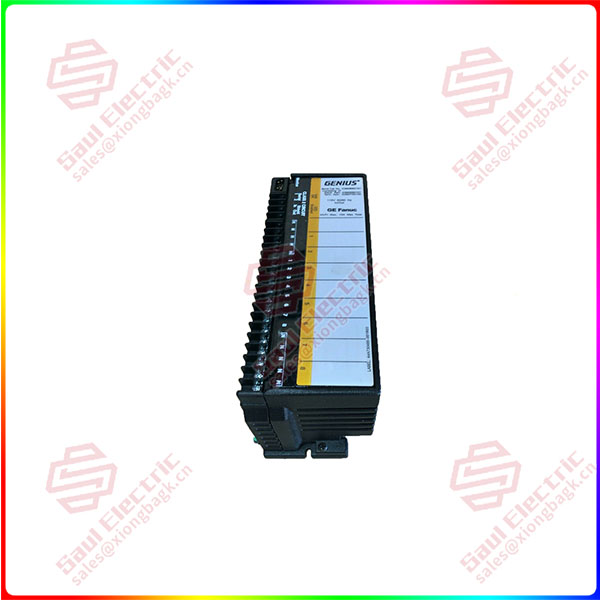

IC660BBD101

Chapters 1-3: Scope, Standard references, and term definitions

The first three chapters of the standard are the same as other standards: Scope, Normative refernces, and Terms, definitions and abbreviated terms. Users can learn which types of machines can use this standard, what other standards are referenced in this standard, as well as specific vocabulary and terminology, to lay the foundation for reading the content of subsequent chapters.

Chapter 4: Security requirements and protection/risk mitigation methods

This chapter focuses on the basic requirements and methods of safety protection, of which Chapter 4.1 focuses on some basic requirements, such as start stop and restart function, scram function, mechanical protection, grating, two-hand control and pressure sensitive carpet, etc., which also refers to a number of relevant Class B standards, such as SCram standard EN ISO 13850. From chapter 4.2 to 4.7, the specific safety requirements of different areas of the injection molding machine are described: Including section 4.2 mold closing area, section 4.3 mold locking structure area, section 4.4 external motion structure, section 4.5 nozzle area, section 4.6 injection molding area and section 4.7 discharge area, the main dangerous motion mechanisms and corresponding protection methods in each area are described. It even includes the requirements for the Performance Level of the relevant safety function or the Protective type for the injection molding machine. Protection requirements against such injuries as heat, noise, falls/trips/falls, pneumatic hydraulic systems, and powered protective structures are also covered in Chapter 4.

1 Year Warranty

1 Year Warranty