In addition, industrial vision as the “industrial eye”, software, hardware and solutions based on machine vision technology, with high perceptual efficiency, high precision and other advantages, is one of the core elements of high-end intelligent manufacturing. The high-precision industrial 3D camera developed by Gaocang Transmission and Midea Blue Orange Laboratory has realized the application of the integrated solution of “camera + software + visual controller + robot”, which is suitable for visual application scenarios with high precision, positioning, assembly and welding, and leads the industry with high precision, strong anti-interference force, extreme design and high intelligence.

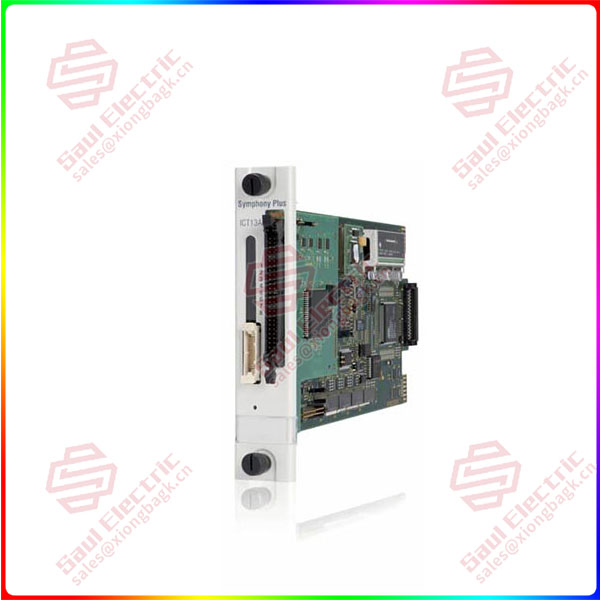

SPICT13A

It is reported that the 3D camera is the first simulation and imaging loop optimization algorithm to adapt to various scenes; It has the industry’s only data generation technology to accurately and quickly generate massive labeled data, breaking the privacy barrier of industrial visual data, and reducing the AI landing time by 95%; The first workpiece-centered processing technology fast configuration scheme to meet the flexible production of workpiece processing and fast processing without teaching; With independent intellectual property rights of 2D/3D vision core algorithm and high-speed robot vision servo and other core technologies, to achieve industry-leading 0.5mm/0.5° accuracy and 200hz high-speed visual servo. At present, Gaochuang high-precision industrial 3D cameras have completed the mass application of robot vision application scenarios such as workpiece loading and unloading, workpiece welding, precision assembly and logistics sorting, such as cooperating with Kuka robots to realize the assembly of core components in the automated production line of Midea smart home appliances.

In recent years, China’s robot industry has achieved vigorous development, and the industrial scale has continued to grow, with the revenue of the robot industry exceeding 170 billion yuan in 2022, and the output of industrial, service and special robots has grown rapidly. With system solutions covering from controllers to encoders, hardware and software, customized products that perfectly match customer needs, 36 years of technical precipitation and experience accumulation, and high-performance products and solutions, Midea Industrial technology’s Gao Chuang will contribute more energy to the core components and key technology breakthroughs in China’s robot industry, and application scenarios.

1 Year Warranty

1 Year Warranty