Cloud-based industrial control system solutions have brought unique industrial control security threats.

With the advent of Industrial Internet of Things (IIoT) technology, OT systems interact more frequently with IT systems. Industrial iot can collect sensor data and control physical processes. When the Industrial iot is connected to cloud-based solutions that constantly push and pull data, it constitutes what is known as a cyber-physical system (CPS).

Scalability, flexibility, high performance, and the ability to integrate with other cloud-based solutions make cloud solutions popular in the field of industrial control systems. The combination of industrial control systems and cloud-based solutions creates unique attack vectors and security challenges for OT systems, including: data residency and sovereignty, cloud data breaches, identity and access management, man-in-the-middle (attacks), compliance with industry-specific regulations and standards, data privacy, and more.

Organizations should establish effective access and identity management, data loss prevention, data encryption, continuous monitoring, recording, and evaluation.

04 How does zero trust approach work in the field of industrial safety?

The zero-trust approach makes a lot of sense in the current chaotic OT system security environment.

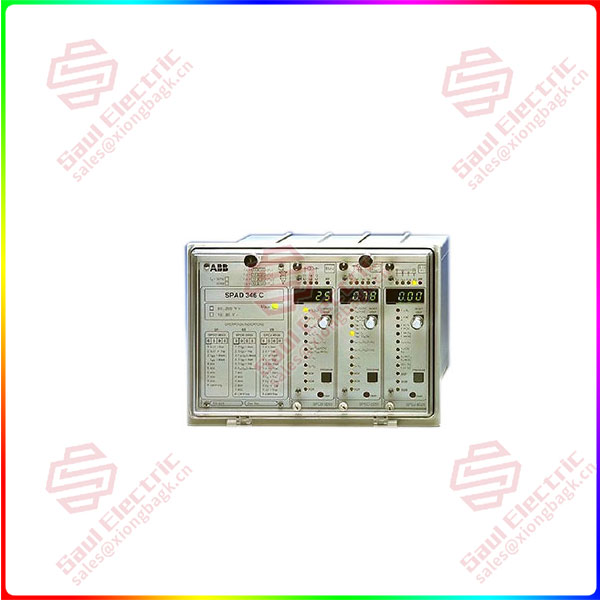

SPAD346C3

OT systems are characterized by diversity, and the introduction of industrial Internet of Things technologies has increased the heterogeneity and dynamics of these systems and networks, especially the rapid growth of machine identities. Zero trust is a key approach to the next generation of industrial security solutions, combined with authentication, minimum access, segmentation, continuous monitoring, automatic threat management, encryption and adapted to OT systems to minimize the potential impact of security threats.

05 What compliance pressures do Industrial Control Systems Network Emergency Response Teams (ICS-CERT) face?

Industrial security regulations and standards issued by the European Union and several countries have a significant impact, especially in the prevention of cyber attacks. Regulations and standards require measures designed to make it more difficult for an attacker to penetrate a system or limit the damage an attacker can cause. While ISO62443 defines the basics of a cybersecurity production environment, laws such as the upcoming NIS2 or Cyber Resilience Act (CRA) require more targeting of the security of the software supply chain.

Since two-thirds of cyberattacks occur through a company’s supply chain, the European Union is now designing stricter regulations here. These create new challenges for companies’ cybersecurity measures, but also provide stronger protection against attacks by cybercriminals. As a result, tools such as SBOM, update management and context-based risk analysis will become an integral part of the future industrial security architecture.

06 What is the passive detection and control strategy for critical infrastructure OT environments?

Given the highly sensitive nature of the large number of sensors and systems deployed in critical infrastructure environments, the need and importance of passive monitoring systems cannot be overstated. Passive monitoring refers to the ability to observe network traffic, system behavior, and anomalies and record them without actively interfering with operational processes. Strategies to achieve this include Intrusion detection systems (IDS), anomaly detection, deep packet inspection, behavior analysis, cyber threat Intelligence (CTI), security information and event Management (SIEM), honeypot, network segmentation, and more.

1 Year Warranty

1 Year Warranty