MDoctor predictive maintenance tool with Codian robot

At this year’s MIIF event, B&R unveiled two precision automation solutions – the MDoctor Predictive maintenance tool and the Codian robot.

B&r MDoctor predictive maintenance tool can extract features from vibration, temperature, noise, oil film, speed, pressure and other signals, and then conduct physical modeling and data-driven modeling based on this, and finally make equipment health status assessment, maintenance recommendations and remaining life prediction through fusion method, so as to provide enterprise users with a reference.

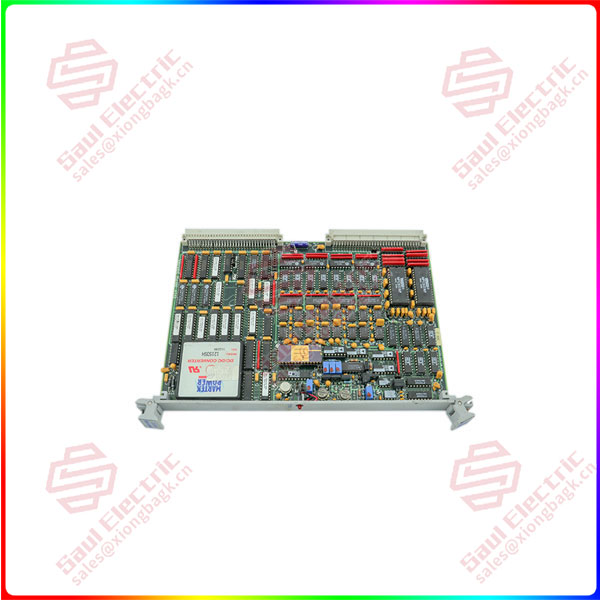

VMIVME-4512

It is the personal “doctor” of enterprise equipment. In addition, MDoctor can also manage multiple devices, bringing enterprises a robust mechanical structure, lower operation and maintenance costs, reduce reliance on labor, avoid unplanned downtime, and ensure the consistency of product quality.

B&r Codian robots currently include D2, D3, D5 series, sanitary and TD4ǀTD5 series. The products have high precision synchronous motion performance, and are fully integrated in the Automation Studio universal development platform. A set of development tools can be applied to the whole machine, with high integration, and simulation and project can be completed simultaneously. The development time of machine equipment is greatly shortened, and the robot is truly integrated in the machine.

1 Year Warranty

1 Year Warranty