Due to exponential growth in the adoption of Industry 4.0 and digital infrastructure, the global automation software market is expected to reach nearly $80 billion by 2030. It is high-tech companies like Germany’s Beckhoff, with their constant growth and pioneering spirit, that have opened the way for this rapid expansion.

The company’s founder and managing director Hans Beckhoff founded Beckhoff Automation in his garage 43 years ago. Today, it has grown into a multinational company with annual sales of $1.6 billion, 6,000 employees and subsidiaries in 40 countries. Since the turn of the millennium, the company has grown at a compound annual rate of 15% – an impressive record.

“We mainly use mature PC control technology that integrates IT and OT in the same platform to achieve equipment automation, building automation, process automation and intelligent equipment automation.” Hans Beckhoff explains. Beckhoff Automation’s products include industrial PCS, I/O and fieldbus components, motion control products and automation software. Today, Beckhoff’s solutions are favored by customers in many different industries such as automotive, wind turbines, logistics, building automation and stage equipment.

In 2021, Beckhoff Automation became a supplier for Emirates Team New Zealand’s America’s Cup, using its EtherCAT technology (Ethernet for control and automation technology) to control hydrogen-powered hydrofoils. Automation of entertainment equipment is also a growing and lucrative industry area for the company. Now, more and more music Tours choose to rely on Beckhoff’s technology to ensure that their audiovisual extravaganza can run smoothly. In the high-tech and nanoscale sectors, several leading semiconductor manufacturers use Beckhoff automation products and systems to control wafer processing chambers. “Automation technology is fundamental to all areas of our society; So the application areas of our products are quite broad.” Hans Beckhoff said softly.

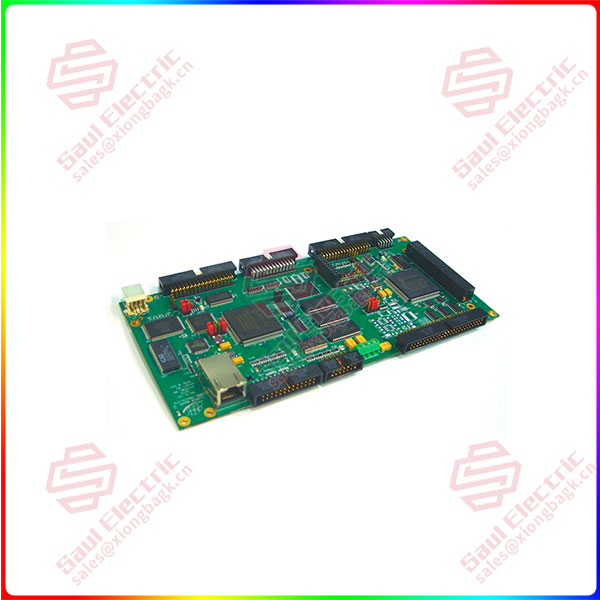

PMAC-2ACC8T

Beckhoff Automation offers high performance control technology for demanding applications. Control response times down to the microsecond level, advanced motion control products, and the integration of machine vision and artificial intelligence all improve device performance, increase productivity, and reduce the ecological footprint. As a result, Beckhoff products are widely used in sustainable technologies such as photovoltaic, wind power and power battery manufacturing.

“One of Beckhoff’s corporate values is that engineers must take responsibility for saving the world!” Hans Beckhoff explains.

High-performance technology can help automate all types of equipment. Machine tools, the plastics processing industry and packaging machinery (to name just three of the many application areas) account for a significant portion of Beckhoff’s business. “The process industry is also a growing market for us.” Hans Beckhoff added.

Beckhoff has a global presence, with 70 per cent of its sales now coming from outside Germany. But from the very beginning, Beckhoff has adhered to the values of family business, which is why the company has been able to operate successfully across borders. “We have built a strong brand reputation for quality and cutting-edge innovation, while also building trust.” He continued, “One of the key cornerstones of our growth strategy is to ensure that we provide support and service to our global customers.” To do this, more than 30 percent of the employees hired by the company are professionally trained engineers, most of whom are hired in local customer operations centers. “Not only do they understand how automation technology works, but they also understand the specific applications of their customers. “Automation is very complex and requires a lot of manpower.”

In such a competitive environment, how to retain talent is a challenge, and Beckhoff has always treated the company as a family and employees as family, and has successfully met this challenge. This has been particularly evident during the COVID-19 outbreak. At that time, the company opened a vaccination center at one of its production sites, which helped vaccinate about 12,000 people, including Beckhoff’s own employees, family members and local residents.

1 Year Warranty

1 Year Warranty