In the past year or two, the low-voltage servo market has gradually started, especially in the AGV automatic guided transport vehicle powered by battery, logistics warehousing and transportation, and some medical equipment applications, becoming the “darling” of the current high-speed development of the mobile robot market.

As a member of the servo “big family”, the current main application scenario is the factory logistics AGV/AMR(automatic guided transport vehicle/autonomous mobile robot), which also comes from the rapid development of China’s high-end intelligent manufacturing, including lithium batteries, photovoltaic, new energy and other emerging manufacturing industries, people dare to boldly try new technologies. In more and more production scenarios, AGV or AMR is gradually adopted to replace traditional manual handling work. AGV is actually a kind of mobile robot, in order to meet the needs of a large range of rapid movement, mainly by the battery DC power supply, the voltage is generally 48VDC, the power range is 50W~1kW, of which 200W, 400W and 750W occupy more than 80% share.

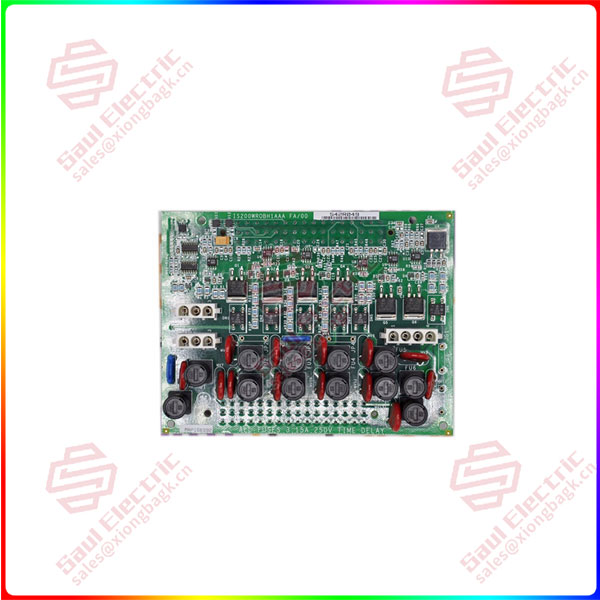

IS200WROBH1A

In terms of structure, AGV mobile robot is composed of vehicle body, battery and charging system, driving device, steering device, precise parking device, motion controller, communication device, load shifting system and navigation system. In the driving device part mainly includes motor, reducer, driver, control and drive circuit, etc., the drive system generally has two closed-loop mode and open-loop mode, AGV motor drive closed-loop mode is mainly based on low-voltage DC servo system.

Generally speaking, the factory AGV for motor volume, load, speed, noise, stability, safety and other performance requirements are particularly high, for this reason, at present, a group of manufacturers represented by Buke Automation specifically for such applications have carried out customized development, combined with low-voltage servo product lines, in terms of volume, overload, efficiency, function and ease of use, for specific scenarios in-depth optimization design. Finally launched the highly integrated “motor + driver + reducer + wheel” four-in-one structural design, greatly reducing the mechanism space of the AGV mobile robot, not only has the low-voltage servo motor system of high response speed, high positioning accuracy of the excellent characteristics, no additional reducer, Moreover, it also meets the demanding requirements of various mobile service robots for low speed and smooth, fast braking, large output, quiet, waterproof and other all-round aspects.

In addition to AGV, AMR, RGV(shuttle) and other specific applications, in fact, the low-voltage servo system in the development of collaborative robots, universal service robots (such as: construction robots, farming robots, logistics robots, life care robots and special medical surgery robots), and even future humanoid robots and other applications are also very promising.

1 Year Warranty

1 Year Warranty