Domestic high-end product supply is insufficient, China needs to speed up the process of PLC autonomy

At present, the problems that PLC needs to solve are still the adoption of new technology, system openness and price. With the expansion of the production scale of the industry, the production automation level of general basic products is improved, the cost-effective advantage is more significant, the competitiveness in the global low-end market is significantly enhanced, and the export volume is growing rapidly. It is worth noting that China’s PLC imports have also maintained a relatively stable growth, mainly due to the lack of supply of domestic high-end products, downstream traditional industries and the sustainable development of new industries, the demand for high-end PLC products growth, the industry’s imports continue to grow.

Domestic brands of PLC in the domestic PLC market share accounted for a small proportion, has not formed an industrial scale, mainly concentrated in the field of small PLC. In 2022Q3, the localization rate of small PLC is about 20.2%, the localization rate of medium and large PLC is less than 10%, and the localization rate of large PLC system is only about 1%.

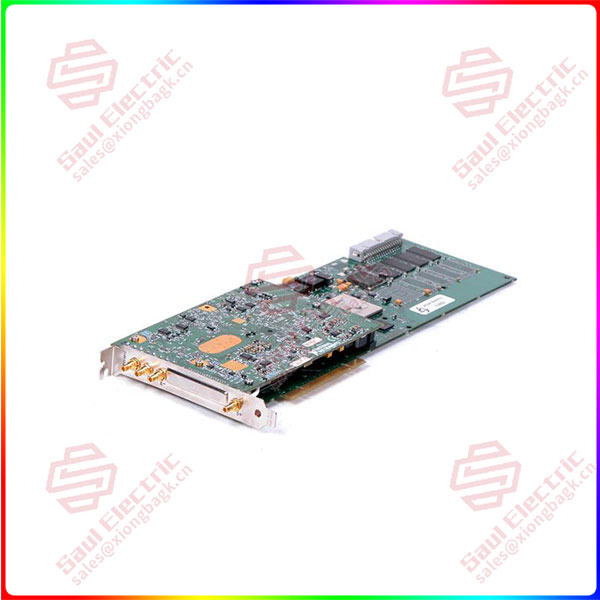

PCI-5412

The domestic industrial infrastructure field for PLC, especially large and medium-sized PLC localization and intelligent voice is getting higher and higher, which also brings opportunities for the local PLC industry curve overtaking. In recent years, with the continuous efforts of domestic industrial control enterprises in product technology research and development and market promotion, many local brands such as Huichuan, Delta, Zhongcong, Hollyse, Fatek, Security Control, Tai ‘an, Fengwei, Aoto, Xinjie, Kowei, Zhenghang and so on actively explore the market. Open source Securities said in the latest research report that domestic manufacturers are seizing the share of small PLC market and Taiwan manufacturers by relying on the advantages of cost-effective products, short delivery time and rapid response to customer needs. Many domestic PLC head companies have been listed in A shares. Under the continuous development demand of emerging industries and traditional industries, the downstream application field of PLC industry has also shown a diversified development trend. In particular, domestic power batteries, automobiles, semiconductors and other industries, as well as traditional manufacturing industries such as textiles and machinery, have become the focus of the future PLC industry to develop markets.

In the era of intelligent manufacturing, PLC technology needs to innovate and optimize

In addition, at the technical level, with the continuous deepening of intelligent manufacturing. The algorithm of PLC software needs to be further optimized for the production requirements of Industry 4.0: on the basis of combining artificial intelligence and big data, the PLC industry should further optimize the software, provide tools that are more in line with the actual application of the industry, improve the ability of industrial algorithms to solve problems and reduce the complexity of the algorithm. In addition, PLC as a tool to assist industrial manufacturing, the underlying program should be further packaged into a simple and easy to use toolkit, to provide a simple interface for technicians to call, to achieve complex production process operation concise.

In recent years, with the continuous popularization of cloud computing in the industrial field, the deployment of cloud PLC in 5G base stations has introduced new blood to the traditional technology of PLC. Based on their own technological advantages in 5G, the three major operators have increased cooperation with traditional industrial control enterprises, laid out “5G+ cloud PLC”, and tried to lay out and seize the intelligent manufacturing market. In 2020, China Telecom’s microwave oven production line in the United States will transform the distributed deployment of PLC in traditional factories and adopt a centralized deployment of PLC based on 5G network. In 2021, China Unicom, Dongtu and Sany jointly released 5G cloud-based PLC applications for global lighthouse factories. In June 2022, China Mobile Research Institute and China Mobile’s Government and Enterprise Division jointly launched the industry’s first 5G cloud chemical industrial base station and completed end-to-end verification.

1 Year Warranty

1 Year Warranty