Honeywell today announced that American Battery Factory (ABF), a manufacturer of lithium iron phosphate batteries, will fully deploy Honeywell’s automation and process safety solutions at its new Gigafactory in Tucson, Arizona.

The new facility covers approximately 18.6 hectares and is expected to be one of the largest lithium iron phosphate battery production facilities in the United States when completed. Batteries produced by ABF create energy storage systems for homes, businesses and utilities to help them optimize energy use on the grid or in internal systems.

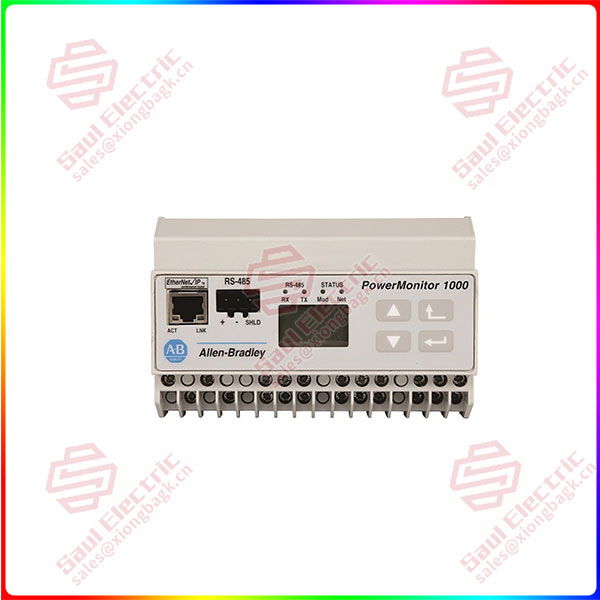

1408-EM3A-ENT

The gigafactory will integrate Honeywell’s innovative end-to-end production management solutions to help ABF optimize production processes and workflows. Honeywell’s technology helps ABF visualize the battery production process in real time, from mixing, painting, assembly to storage and distribution, to streamline and improve the collection of operational data, and to gather insights for operators about subsequent tasks or potential delays, ultimately increasing production and reducing waste. More energy efficient and cost effective battery production.

“With Honeywell’s superior tools and technology, we can quickly and efficiently build a sustainable foundation for our Gigafactory network.” John Kem, president of ABF, said, “This partnership marks substantial progress toward our goal of providing a national supply of U.S.-made lithium iron phosphate batteries, which is critical to meeting federal and state climate change initiatives.”

“Honeywell’s innovative solutions play an important role in ABF’s growth.” “Our solutions in battery automation and process control help expand production and reduce consumption, and have the potential to change the way gigafactory operations of the future,” said Chad Briggs, vice president and general manager, Program and Automation solutions, Honeywell Process Control.

1 Year Warranty

1 Year Warranty