On October 7, the first 100% domestic large fan – Vision Energy’s latest offshore low-wind speed prototype was rolled off the production line in Vision Jiangsu Sheyang Zero-carbon Industrial Park. This series of models is based on the previous generation of low-wind speed order King EN-226/8.5MW comprehensive upgrade, with a maximum wind wheel diameter of 252 meters leading low-wind speed offshore products, power class coverage of 10.5-12MW, to help customers obtain better electricity costs, is expected to be delivered in batches at the beginning of 2024 State Power Investment Guangxi Qinzhou offshore wind power demonstration project. Not only that, this series of new models is also suitable for Jiangsu, Shandong, Zhejiang and other sea areas of the best model.

It is estimated that the downline model sweep area exceeds 4.7m²/kW, the total power generation is increased by 25%, and the estimated yield of typical scenarios can increase by more than 10%. The model is equipped with high-torque gear box, compact dry transformer, new electric transmission chain and other fully independently developed core components, 90% of the core large components have completed bench testing and verification, and successfully obtained the whole machine type certification. Thanks to the continuous improvement of self-developed core technology and 100% domestic supply chain support, performance and reliability can be improved while effectively reducing costs and ensuring delivery flexibility.

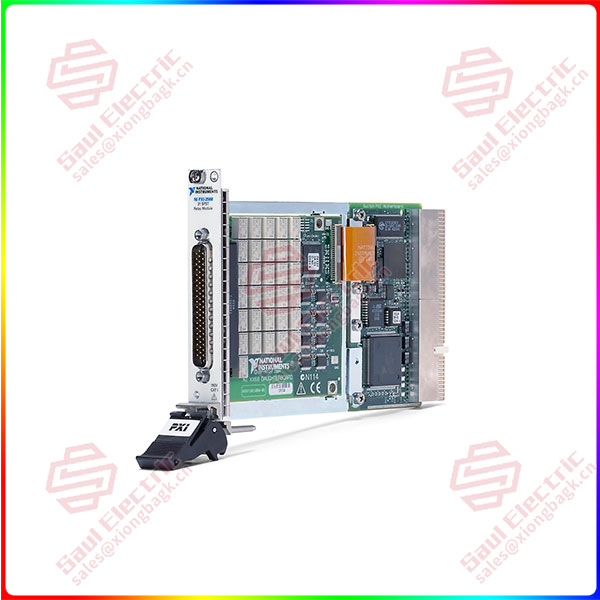

PXI-2568

The process of continuous realization of comprehensive localization of large fans is not easy, how to open up the upstream and downstream of the supply chain? How to realize information sharing and promote technological innovation? As the main chain of the supply chain, the role of the whole machine supplier is very crucial. Taking the generator as an example, the vision sea and land models of generators have fully realized self-research and localization, the selection of well-known domestic generator manufacturers OEM production. Through the whole control of the parts supply chain, the resident supervision personnel to implement the process requirements, to ensure that the same model produced by different manufacturers, the design, interface, power generation performance is not different. Up to now, Vision has delivered more than 10,000 self-developed motors. Driven by the head of the whole machine business, the resources and quality of the entire industry chain are aligned, and the confidence of the industry chain is also boosted, entering a virtuous cycle of supply and demand.

So, what has shaped the full localization of large wind turbines? The answer is obvious, is from the deep insight of the underlying technical logic and law, through the self-research of large components, complete the core technology and innovation, on the basis of solving the problem of jam neck, to ensure that the research and development of the unit can play the best match the performance of China’s wind conditions. Vision is the first in the industry to open the design and manufacturing of large parts of the black box, to realize the core strategic components such as blades, gearboxes, generators, frequency converters, variable pitch bearings and other completely independent intellectual property rights, as a solid guarantee for 100% domestic large fans. The off-line model is equipped with the vision self-developed self-extinguishing dry type transformer, smaller volume, higher safety, more convenient operation and maintenance; And the E-TOP structure, innovative design of independent cabin, more improve safety and scalability.

The localization of wind power reflects the enterprise’s investment in research and development and its confidence in solving the problem of congestion, as well as its comprehensive strength in technological innovation, testing and verification, engineering and manufacturing, and supply chain coordination. From the establishment of the first offshore wind turbine in 2013 to the realization of 100% localization of large wind turbines in 2023, it is proof of the progress of the vision’s own strength, and it can also be explained from the side that China’s wind power manufacturing industry and green technology level have been like large wind turbines at sea, standing tall in the waves.

1 Year Warranty

1 Year Warranty