“G” series harmonic reducer is specially developed for high torque customers, the whole machine structure is compact, to meet the needs of high torque, high load, high reliability, compared with LH and LS standard series, torque capacity increased by more than 30%, service life increased by more than 43%.

“N” series harmonic reducer is a lightweight product, through the optimization of structure and material, in the case of ensuring sufficient stiffness, strength, life, compared with the standard series weight reduced by more than 30%. Not only the mechanical equipment itself is lightweight, but also the lightweight of industrial robots can achieve its high-speed and increase the load weight.

“Mini” series harmonic reducer with its small size (coin size), low back backlash, high torque characteristics, become an excellent choice for industrial robots in smaller space operation.

At this year’s Expo, Raffles also launched a new product line – joint module for the first time. This series of innovative products will inject new impetus into the field of robotics and automation equipment, providing users with more choices and solutions.

Joint module is an indispensable part of robot motion control, Raf self-developed high pressure and low pressure joint module using advanced materials and processes, with lightweight, modular, easy assembly, easy maintenance and other advantages, suitable for a variety of hollow turntable scenarios, capable of various complex tasks, widely used in the field of collaborative robots, service robots, foot robots and other fields.

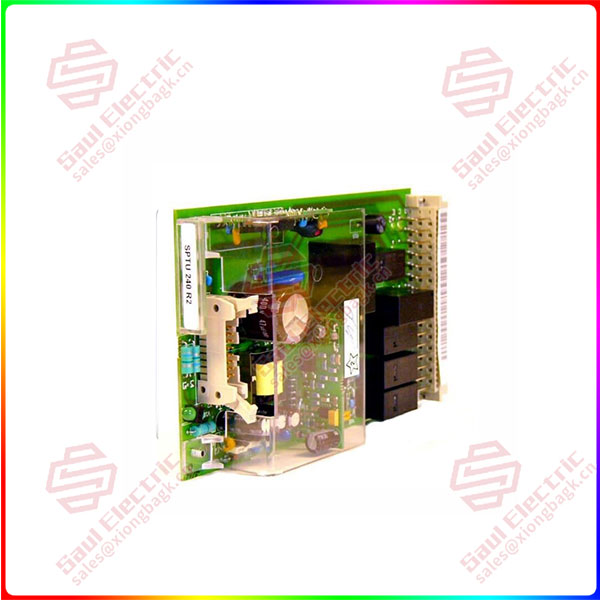

SPTU240R2

As an important force of domestic harmonic reducer, Tongchuan Precision has focused on the research and development of robot core components since its inception, in order to break the monopoly situation of overseas brands and realize the localization of robot core components as the goal, and is committed to providing safe, reliable, modular and lightweight precision transmission components for the robot industry. At present, the company’s products mainly include harmonic reducer, mechatronics actuator, joint module of cooperative robot, joint module of humanoid robot and so on.

Under the leadership of the core technical team, Tongchuan took the lead in developing advanced gear reducer tooth shape – 3D curved conjugate double circular arc tooth profile, to achieve a breakthrough in domestic harmonic gear reducer technology, effectively improve the harmonic gear reducer service life, transmission accuracy, consistency, vibration noise and other performance and quality, technology and product parameters are fully leading, the overall performance has reached the international leading level.

In the development and production of harmonic reducer, Tongchuan precision captures customer and market demand, brings forth the new, cleverly combines the reducer, motor, encoder and brake to create a high-precision, high-rigidity, high-torque and small-volume harmonic mechatronics actuator. At the same time, it has also laid out and mastered the relevant technology of robot transmission in advance, launched a series of robot transmission joint modules for collaborative robots, humanoid robots, and service robots, further reducing the volume and weight of robot joint modules, and achieving a high degree of integration.

Shen Xiaolong, founder of Tongchuan Precision, once said, “The first scale of robots will happen in China.” Tongchuan Precision will also contribute to the development process of the robot industry and accelerate the development process of the era of artificial intelligence.

peroration

At Tesla’s 2023 shareholder meeting, Musk said that in proportion, the ratio of humans to robots is greater than or equal to 2:1, which means that the demand for robots will reach 10 billion units or even more. At the same time, Musk also believes that the vast majority of Tesla’s future market value will be contributed by humanoid robots, affirming the importance of humanoid robots and Tesla’s strategic layout.

Humanoid robots accelerated evolution, domestic harmonic reducer due to low prices, hardware conditions have reached the humanoid robot requirements, domestic manufacturers significantly increased competitiveness, is expected to occupy a larger market share.

1 Year Warranty

1 Year Warranty