Description

Overview

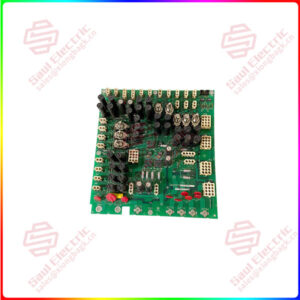

Essential details:8273-140 2301D Woodward Load Sharing and Speed Controls

The new 2301D and 2301D-EC software will operate with all existing 2301D / 2301D-EC controls, or any controls with analog load sharing. There will be some differences in the PID settings, particularly the GAIN, RESET, and ACTUATOR COMPENSATION. If replacing an old part number, leave the new part number’s Gain, Reset, and Actuator compensation at default values to begin the tuning process. Do not copy the PID settings from and old unit to a new one. Manual 26288 lists some settings for various engines.

New PID Algorithm and Adaptive Speed Sensing Filter

The PID was changed to allow the 2301D to better control slow and medium speed engines.

The speed sensor, as it measures speed, will only send an output to the PID with a new speed only if the engine speed has actually changed. This helps in control of slow speed engines.

The adaptive speed sensor learns or adapts to any anomalies in the gear teeth, torsionals, and slow speed firing frequency.

There are now three ways of selecting the method of speed sensing:

Speed Sensor Function 1 is used for medium and high-speed engines. Typically use this speed sensing type for MPU frequencies of 1000 Hz. and above. The MPU gear is divided into 16 pieces; therefore the speed is sensed and updated once every 1/16th of a full engine revolution.

Speed Sensor Function 4. The speed is sensed on every timing pulse. This function is specifically designed to give readings at low speeds. Speed is calculated by using only two inter-tooth time intervals. This function measures the time between each tooth and stores the two most recent measurements. This block samples and averages these two measurements each time the block executes and uses the average to calculate speed.

Speed Sensor Function 5 is specifically designed with an adaptive rotational speed-sensing filter. This filter will give stable speed sensor readings for:

– Low and medium engine speeds.

– Engine torsional frequencies caused by engine firing frequencies or various engine loads.

– Noisy MPU signals caused by run out in the gear, irregular shaped gear teeth or irregular shaped holes in the flywheel.

There is no correlation between the PID settings of the different software’s.

8273-140

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

8273-140 2301D Woodward Load Sharing and Speed Controls

1 Year Warranty

1 Year Warranty