Xingwei QD750C industrial cleaning robot

Star to QD750C industrial cleaning robot was born in industry, service industry. With the nearly perfect “hexagon attribute”, it is trusted by leading enterprises in various industries, and has been widely serving lithium battery, photovoltaic, tobacco, automotive, aerospace, auto parts and traditional energy industries.

The robot is designed with compact structure, high cleaning efficiency, a wide range of operations, and equipped with a large-capacity water tank, which is more suitable for long-term cleaning operations. It can realize system linkage with mainstream AGV/AMR, effectively solving the industry problems that affect production efficiency after the introduction of cleaning robots by enterprises. With a powerful cleaning unit, it can effectively remove stubborn pollutants from industrial sites, and the robot can be equipped with additional abrasive discharge devices to achieve deep cleaning functions. Through the intelligent iot function, the screen door can be automatically opened, and the system control mode can be automatically switched to achieve a larger area of job coverage.

Collaborative robot gluing application

Siasun GCR5-910 collaborative robot is equipped with an electric glue gun at the end. While running accurately according to the specified trajectory, the robot can autonomously control the gluing time and speed of the gluing system to ensure uniform and beautiful gluing, with high flexibility and high stability, and significantly improve the production rhythm, glue utilization rate and production quality.

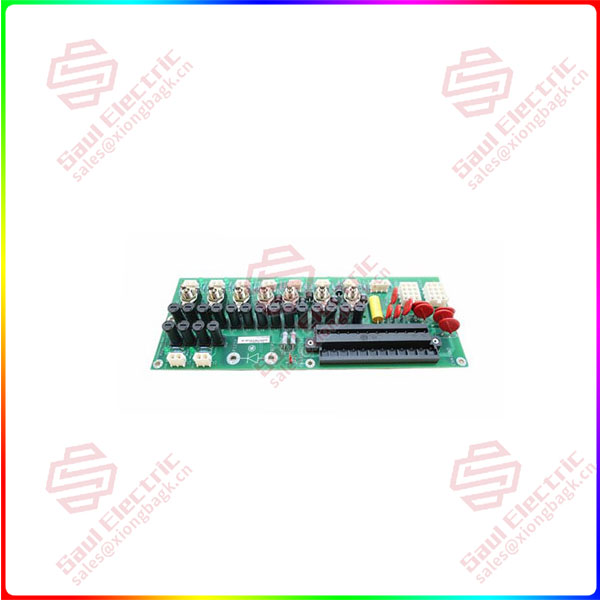

IS200EPDMG1B

Collaborative robot screw tightening applications

Siasun GCR14-1400 cooperative robot is equipped with an automatic tightening module at the end to realize automatic screw feeding and flexible tightening operations. The feeder controls the nailing speed through the control unit and reminds the feeder of lack of material. The screw in place sensor is used to detect the screw in place in the tightening module. The electric CNC screwdriver is used to detect the screw in place through the depth sensor and the torque monitoring feedback to confirm the screw in place. This application shows the excellent repetitive positioning accuracy of Siamatsu cooperative robot, which is capable of intelligent tightening work in multi-position and multi-angle.

Siasun has an industry-wide value chain integrating core technology, core components, core products and system solutions. In this exhibition, Siasun not only exhibited a series of robot products and software products with independent intellectual property rights, but also brought many types of core parts and ecological products to the show! At the exhibition site, Siasun self-developed servo motor, servo drive and other core parts and components products were unveiled.

Based on independent innovation, Siasun will continue to launch more innovative software and hardware products, provide more solid support for promoting new industrialization, building a manufacturing power and a network power, and add new vitality and inject new momentum for Chinese-style modernization. October 18th – 20th, New World Expo Shenyang L4 Hall 4B-15 booth, Siamatsu will see you!

1 Year Warranty

1 Year Warranty