At present, the global industrial intelligence network is in a critical period of accelerated technology incubation, application scenario expansion, and scale expansion, and the industrial pattern has not yet been fully determined, with great development potential.

In terms of industrial status, the United States, China, Japan and Germany, relying on the original industrial Internet industrial base, have certain first-mover advantages in industrial intelligence networking; In terms of technology trends, innovation is mainly concentrated in two directions: core enabling capability and engineering application. In terms of industrial ecology, new links, new processes and new subjects continue to emerge; In terms of ecology as a whole, multiple entities are strengthening cooperation, and technical standards and development security are paid more attention.

The scale of basic industries in the United States, China, Japan and Germany is dominant, and upper-middle-income countries are grasping the opportunity

Based on data from the Organization for Economic Cooperation and Development (OECD) and the World Bank, the China Industrial Internet Research Institute has measured the industrial Internet industry scale in 59 representative countries around the world. In 2020, the total added value of the industrial Internet in 59 countries will be 3.74 trillion US dollars. The top four are US $885.84 billion, China 566.456 billion, Japan 305.566 billion, Germany 247.594 billion, the total size of the US, China, Japan and Germany more than 50% of the global scale.

According to the income level, the total scale of high-income countries reached 2.55 trillion US dollars, accounting for 68.12%, with a growth rate of 1.41%; The upper middle-income countries accounted for US $0.94 trillion, accounting for 25.21%, with a growth rate of 7.34%; Lower-middle income countries accounted for $0.25 trillion, accounting for 6.67%, with a growth rate of 1.59%.

It can be seen that high-income countries rely on their own existing developed industrial system, in terms of industrial base has a first-mover advantage, but China, Russia, Brazil and other upper-middle income countries are trying to seize the new round of technological revolution and industrial revolution development opportunities, strengthen the application of industrial intelligence networking in the national economic system, and strive to achieve the development of industrial intelligence networking “curve overtaking”.

Technological innovation is mainly oriented to the growth of core enabling capabilities and engineering applications

The current industrial intelligent networking technology innovation is mainly aimed at two directions, one is the upward oriented core enabling capability growth technology innovation for more complex knowledge processing and higher performance requirements, and the other is the downward oriented engineering breakthrough application innovation for industrial deployment.

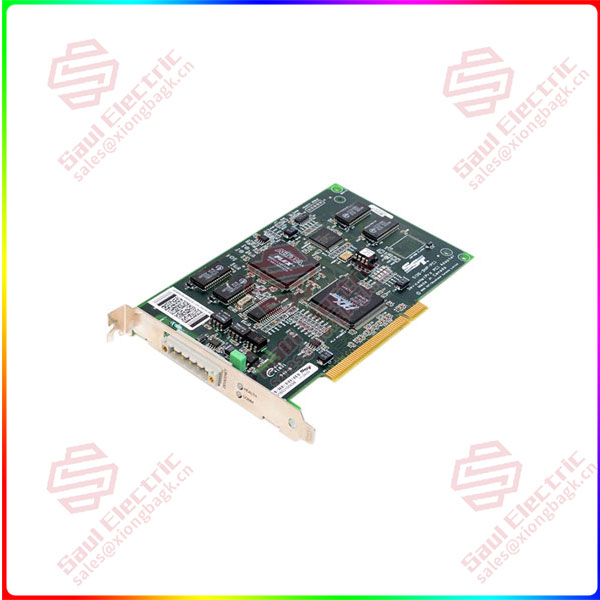

5136-DNP-PCI

In terms of core enabling capabilities, first, data science innovates around more complex and diverse industrial problems with deep learning at its core. Deep reinforcement learning (DRL) optimizes the execution of multiple decisions in dynamic environments and complex scenarios by iterating trial and error in industrial practice, demonstrating powerful optimization capabilities in product design and development, scheduling control and processing path, operation and maintenance management and strategy. The adversarial network (GAN) is generated, and the number of effective industrial samples is increased, the quality of industrial data is improved, and the data basis for the training of industrial models is provided through the continuous game of two neural networks.

Second, based on deep learning, application innovation focuses on improving the ability to identify key problems and provide knowledge services for production and customers. Industrial vision technology is more focused on high-precision small target recognition scenarios, as well as processing power in low-quality data situations. Natural language processing (NLP) focuses on user service, improves user interaction recognition ability, and deeply digs customer needs by analyzing knowledge graph to improve service efficiency and quality.

Third, knowledge engineering is moving towards mapping, automatic construction and updating, and quantitative complex decision making. The core links of data acquisition, knowledge processing and knowledge application of industrial knowledge have been defined, the automatic construction and updating framework of industrial knowledge graph has gradually taken shape, the semantic processing link has changed from manual processing to automatic extraction and fusion, the graph updating link has realized dynamic organization and self-updating, and some institutions have established an “open crowdsourcing” mechanism for knowledge graph management.

Fourth, the way industrial robots interact and learn is changing to the direction of man-machine, brain-like, and brain-machine technologies. Technological breakthroughs such as bidirectional brain-computer interface and brain-like + brain-computer interface will profoundly change the man-machine collaboration model and will gain interpretable experiences from machine learning, but this field is still in the theoretical research and experimental stage.

In terms of engineering applications, first, chip and model software and hardware work together to solve the problem of model efficiency. At present, the chip architecture dominated by von Neumann structure is facing the challenge of “memory wall”, and domestic and foreign AI enterprises and chip manufacturers have launched hardware such as acceleration modules and edge computing boxes, focusing on the direction of architecture design and scene optimization to carry out diversified exploration. At present, the model efficiency improvement technologies such as distillation of knowledge graph structure, knowledge rectification and parameter pruning quantification have attracted wide attention, but their specificity and academic characteristics are strong, which limit the industrial implementation and promotion.

Second, improve process interpretability in areas such as equipment management and process optimization. On the one hand, in the scenes of quality detection and equipment anomaly recognition, the causality/correlation relationship is mined based on the feature visualization method, and the visual output is carried out. On the other hand, in scenarios such as fault root analysis and production defect prediction, local/global approximations of interpretable models such as decision trees, decision rules and industrial knowledge graphs are used to improve interpretability.

Third, focus on the small sample dilemma and industry domain data set construction problems to improve data availability. The dilemma of small samples lies in the fragmentation, marginalization and weak relevance of industrial data, which makes it difficult to extract knowledge. At present, there are mainly several solutions such as data expansion, introduction of prior knowledge and optimization of model structure.

Fourth, the AI framework has gradually become the core field of accelerating industrial integration and large-scale landing. On the one hand, it provides a unified and scalable infrastructure layer to improve the model training performance, on the other hand, it makes directional adaptation and specific optimization for the target hardware to ensure the end-to-end model deployment and reasoning speed, and the ultimate goal is to improve the adaptation and ease of use of the AI framework, and promote industrial integration and large-scale landing.

1 Year Warranty

1 Year Warranty