The old team “wisdom” is strong

The analysis of prospective Industry Research Institute pointed out that from 2010 to 2020, the output value scale of China’s intelligent manufacturing industry has risen year by year; In 2020, the output value of China’s intelligent manufacturing industry will be about 2,505.6 billion yuan, an increase of 18.85%. It is expected that China’s intelligent manufacturing industry will maintain an average annual compound growth rate of about 15% in the next few years, and this scale will reach about 5.8 trillion yuan by 2026.

The market size has risen year by year, reflecting the huge development space in the field of intelligent manufacturing, which has also attracted the participation of many enterprises. From the technical point of view, science and technology enterprises with strong scientific research strength and rich intelligent practical experience have innate advantages in the field of intelligent manufacturing, and should also become one of the leaders of this national major strategic planning.

As a “veteran” of the manufacturing industry, Lenovo Group has also continuously written a “new biography” in the field of intelligent manufacturing. Based on the “end-edge-cloud-network-intelligence” all-factor technology architecture, Lenovo Group has developed five capabilities, including intelligent supply chain management system, highly automated mixed-line flexible production, virtual and real combination in product design and manufacturing process, end-to-end quality traceability, monitoring, analysis and management, and predictive analysis and decision-making driven by big data and artificial intelligence. And in Wuhan, Hefei, Shenzhen to create intelligent manufacturing “iron triangle”.

Among them, Wuhan factory independently developed 5G+IoT automation production line “quantum line”, through 5G network and edge computing, cloud computing platform collaboration, so that product delivery efficiency increased by more than 20%; Lianbao Technology is the world’s largest PC research and development and manufacturing base and national intelligent manufacturing demonstration base of Lenovo Group. Lenovo Southern Intelligent Manufacturing Base will improve the production efficiency of the whole chain through the combination and application of intelligent logistics, intelligent scheduling and intelligent production lines.

In addition, in order to efficiently control the production situation of the supply side and accurately predict the market demand, Lenovo Group independently developed the intelligent control tower of the supply chain in 2017, and used it as the intelligent brain and command center of the global supply chain, and dynamically coordinated the global supply, production, sales and service resources by building a data-driven intelligent supply chain ecosystem.

At the moment when intelligent transformation and upgrading has become a new engine for high-quality development of the real economy, in order to continuously improve the level of intelligence and digitalization, Lenovo Group continues to increase investment in scientific research and strengthen the reserve of core science and technology talents.

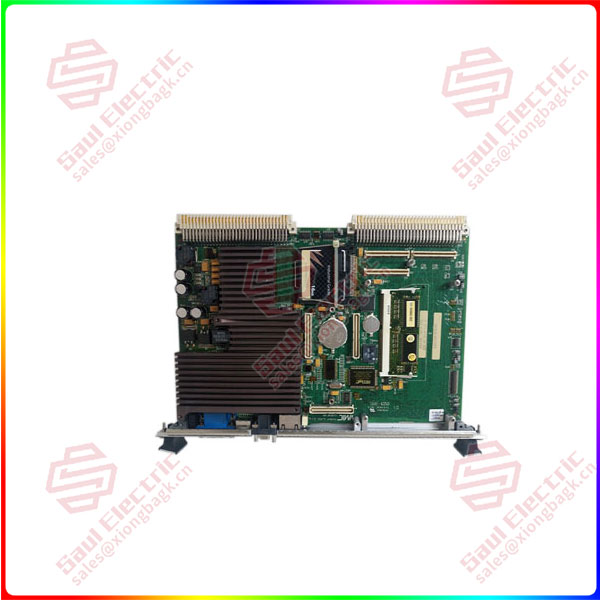

IS215UCVEH2AE+TPMC815-11=IS215UCVEM08B

Yang Yuanqing, chairman of Lenovo Group, has said that by the end of the 2023/2024 fiscal year, Lenovo Group’s research and development investment will double from the 2020/2021 fiscal year. In the next five years, Lenovo’s total investment in research and development will exceed 100 billion yuan.

Not only that, Lenovo Group also announced in 2021, on the basis of more than 10,000 R & D personnel, launched the “global large-scale core science and technology talent recruitment plan”, the next three years in the global scale for society and universities to recruit 12,000 science and technology talent, all-round enrichment of the three-level innovation system. It is reported that nearly 5,000 people have joined Lenovo’s research and development team in the past year.

In the process of intelligent transformation, Lenovo Group has become internal and external, and continues to empower the intelligent upgrading of the industry. For example, with the advantages of big data, Internet of Things and artificial intelligence, Lenovo Group has established an intelligent pipe and semi-automatic welding machine welding intelligent management system for Sinopec Petroleum Engineering Construction Co., LTD., which reduces energy consumption in production while improving quality and efficiency.

It can be said that Lenovo Group, based on its manufacturing strength accumulated in the field of manufacturing for decades and the digital experience accumulated in the process of intelligent transformation, has opened up a new path for China’s intelligent manufacturing, and has also become a microcosm of the development of a strong and empowered industry in the manufacturing field.

Haier Group, the home appliance giant, is also a global pacesetter of intelligent manufacturing. According to the list of the eighth batch of global lighthouse factories released by the World Economic Forum, following Jiaozhou central air conditioning, Shenyang refrigerator, Tianjin washing machine, Zhengzhou Haier water heater interconnection factory was selected as “light tower factory”. At present, Haier Group is one of the enterprises with the largest number of “lighthouse factories” in China.

Ningde Times, a leading power battery company, began its layout in the field of intelligent manufacturing in 2011, and has now completed the transition from automation to automation + digitalization, and then to intelligence in three stages. With the update and iteration of technology, the focus of the future Ningde era will be on the deep integration of production line and AI intelligence, big data, cloud computing, etc.

From poor to manufacturing power, and then from manufacturing power to manufacturing power, this process is to fight technology and innovation. Intelligent manufacturing has been the trend of The Times, and all sectors of society have a clearer understanding of this, and the increasing investment in technological transformation of manufacturing enterprises is the embodiment of this trend and awareness. With the continuous innovation and upgrading of technology, as well as the vigorous promotion of many science and technology enterprises, the realization of the goal of manufacturing power is just around the corner.

1 Year Warranty

1 Year Warranty