Visual data signage and environmentally friendly materials unlock carbon reduction potential

The rapid development of modern industry has accelerated energy consumption, “double carbon” goal, double control of energy consumption has been the consensus of the industry, manufacturing factories as energy consumers need to focus on energy saving and consumption reduction, to achieve green production. With the ABB Ability™ EAM digital solution, it is possible to identify and analyze the power consumption of the equipment in the plant from multiple angles, forming a visual kanban for horizontal and vertical comparison and identifying opportunities for energy efficiency improvement. At present, ABB electrical engineers have completed the classification and summary of the existing energy efficiency data of the Gigafactory based on their rich experience in power distribution operation management, laying the foundation for the use of backup circuits in the future.

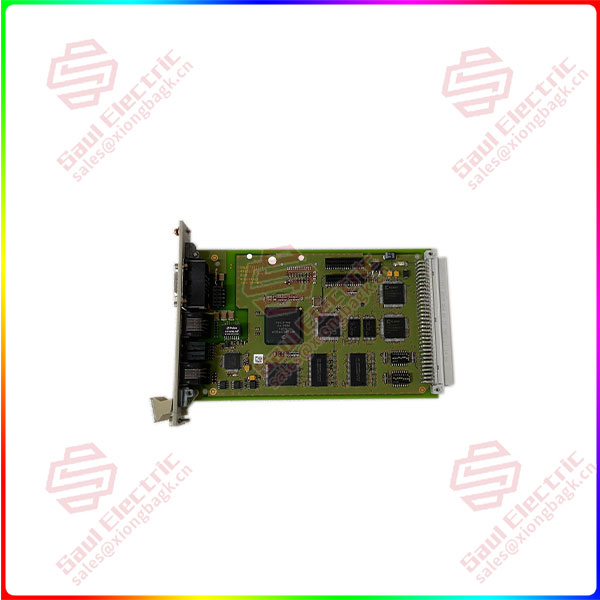

F8627X

The VD4 vacuum circuit breaker uses an environmentally friendly PT solid seal pole, an environmentally degradable material that ensures that its manufacturing process emits only 40% of the carbon emissions of similar products, reflecting ABB’s commitment to sustainability and carbon reduction, combined with safe and reliable design and intelligent configuration to continue to create new value for customers.

Luo Jing, acting head of ABB’s Robotics Business unit in China, said: “ABB Robotics is committed to helping enterprises in different fields and sizes enhance development resilience, improve operational efficiency and improve production flexibility through the application of robot automation technology. ABB Electric’s digital power distribution solutions help our Gigafactory further achieve digital connectivity and efficient management from its own production and operations, creating a green benchmark factory.”

Zhao Yongzhan, president of ABB Electric China, said: “ABB adopts the high-quality development path of digitization and electrification to decode the manufacturing industry, so that every hour of electricity and every energy consumption can achieve lean management, actively help high-end intelligent manufacturing, and enable carbon neutrality.”

1 Year Warranty

1 Year Warranty