Watch 09 Digital twins need standards?

The digital twin lacks standard EL3040 guidance and reference in the process of landing application. The author’s team and the relevant technical standards committee and application enterprises have jointly explored and established the digital twin standard system framework, from the basic common standards and key technologies of digital twins

The digital twin standard system is studied in six aspects: standard, tool/platform standard, evaluation standard, safety standard and application standard. However, the specific standard content of each digital twin in the established standard system still needs further research and formulation.

In addition, it is reported that the International Organization for Standardization Automation Systems and Integration Technical Committee (ISO/TC184) is carrying out research on digital twin construction principles, reference architecture, digital representation of physical manufacturing elements, information exchange and digital twin visual elements. IEEE Digital Twin Standard Work (IEEEP2806) is conducting research on digital representation and system architecture of physical entities in smart factories. The Digital Twin Advisory EL3040 Group of the ISO/IEC Joint Technical Committee on Information Technology Standardization has conducted research on the terminology, standardization requirements, related technologies, reference models and other aspects of digital twins, but no specific digital twin standards have been published.

To sum up, the development and application of digital twins need the guidance and reference of standards, and the formulation of international standards for digital twins is the focus of current national attention.

10 Digital Twins Need commercial tools and platforms?

With the gradual emergence of digital twin application value, more and more enterprises expect to use digital twins to improve enterprise efficiency and improve product quality. In the process of practicing digital twins, “what tools/platforms to use to build and apply digital twins” is the problem faced by enterprises.

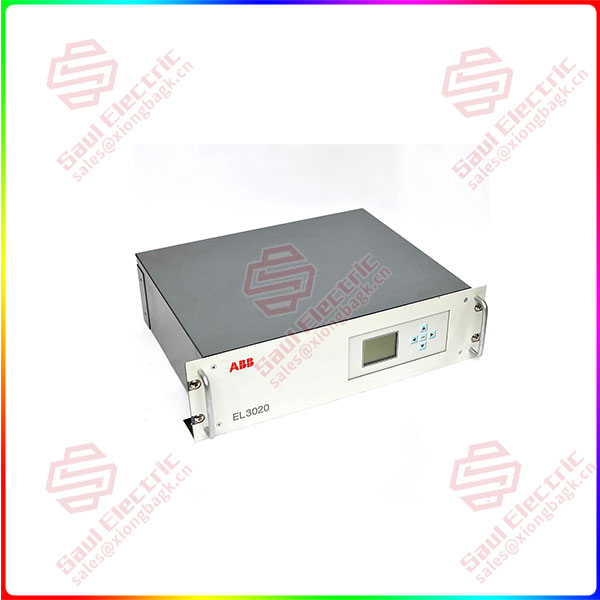

EL3020

There are already commercial tools and platforms that support digital twin construction and applications, such as MATLAB’s Simulink, ANSYS’s TwinBuilder, Microsoft’s Azure, Dassault’s 3D Experience, and others.

However, from a functional point of view, most of these tools and platforms focus on one or some specific dimensions, and currently there is a lack of commercial tools and platforms that consider the comprehensive functional needs of digital twins. On the other hand, from the perspective of openness and compatibility, relevant enabling tools/platforms mainly form a closed software ecosystem for their own products, and it is difficult to interact and integrate models and data between different tools and platforms, difficult to collaborate, poor compatibility, and lack of digital twin construction tools and platforms with system openness and strong compatibility.

In addition, due to the mastery of relevant specific data, EL3040 processes, processes, principles, etc., it is relatively easy for product developers or providers to achieve the construction of digital twins, while third parties (such as system integrators, product end users, product operation maintainers, etc.) have many difficulties in the construction of digital twins, resulting in the construction of digital twins has become one of the bottlenecks in its application and promotion.

With the development of related technologies and the evolution of product research and development mode, the construction of digital twins in the future may no longer be a key problem that puzzles users. For example, in order to improve the quality and research and development efficiency of their own products, leading enterprises will require researchers or providers to provide the corresponding digital twin model while providing the physical entity of the product. In the future, how to realize the assembly and integration of different digital twins based on the digital twins provided by different users and the construction requirements of digital twins for complex products, complex systems and complex processes will become a new difficulty, requiring relevant commercial EL3040 digital twin integration tools and platform support.

To sum up, the implementation and promotion of digital twins need the support of commercial tools and platforms with comprehensive functions, open and compatible systems, and strong integration. In addition, there is a lack of commercial tools and platforms for digital twin evaluation and testing.

1 Year Warranty

1 Year Warranty