Innovative benefits of SIS security systems

Founded in 1983, the Triconex brand has more than 40 years of application experience in functional safety and critical control. The software and hardware platform design also covers ESD emergency shutdown system, F&G fire gas protection system, HIPPS high integrity pressure protection system, TMC turbine control and protection, DEH turbine control system, BMS burner management system and other safety applications.

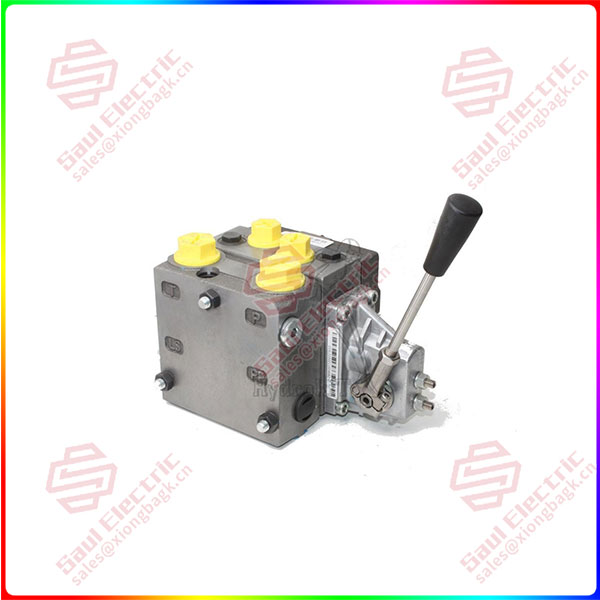

PVG32-1 The EcoStruxure Tricon CX safety instrumentation system has a special package for unit control that has been repeatedly verified in the field, and its comprehensive application function is very strong. In particular, the TMR triple redundancy design structure of the system is not only a simple processing unit (CPU) three redundant voting, but composed of the input, CPU, and output of the whole channel triple voting calculation. The design of this structure principle not only helps to improve the reliability and availability of the system itself, but also helps to improve the reliability and availability of the system. And in the project application of integrated design, use and maintenance also provides great convenience.

(3) Complete process integration solution

Large and complex process industries such as integrated refining and chemical plants call for more PVG32-1 integrated system platforms. Schneider Electric’s integration of process automation and digital solutions is mainly reflected in:• Integrated DCS engineering application platform – EcoStruxure Foxboro DCS system platform software, now formed based on database, data management, DCS configuration management, DCS program development, DCS screen development, equipment management and other functions together integrated platform, can also provide based on.

PVG32-1

NET open interface, can integrate many third-party applications on the software platform.

PVG32-1 EP&P (EcoStruxure Power and Process) Integrated energy management and process automation – Historically, distribution management and process automation have been designed and operated independently throughout the plant life cycle. In the Schneider Electric EP&P integration solution, traditional electrical equipment is connected to the system via industrial Ethernet based on the IEC61850 standard through a dedicated power controller that supports redundancy – this means that electrical equipment can be seamlessly connected to the DCS network for programming configuration and even device control. The main advantages of this integration are to reduce the complexity between systems to simplify project execution and post-operation, and to meet the special energy needs of electrical/automation/operations personnel through rational optimization of power and production process parameters, as well as to minimize the overall operating costs and PVG32-1 carbon footprint of the plant by optimizing the management of different energy types.

• Integrated plant from process to operation – Based on Schneider Electric AVEVA Industrial software, throughout the entire life cycle of design, construction, operation and maintenance, including AVEVA APC advanced process control and optimization with integrated DCS system, extended to engineering procurement and construction, planning and scheduling, operations and asset performance management software platform. Further help to build an integrated process factory.

Nowadays, with the continuous development of the process industry, new process plant technologies and integrated factories have brought new requirements to process automation, and process automation itself has long gone beyond the scope and concept of DCS. Through continuous innovation and deep integration, Schneider Electric Process Automation is committed to helping more and more process industry customers win the new industry pattern of the future.

1 Year Warranty

1 Year Warranty