Automatic control is always the focus of the factory, whether it is intelligent manufacturing, or the industrial Internet, can not be avoided. Recently, there has been a lot of discussion about the two controllers PLC and PC-based control. In fact, the debate over these two kinds of controls has a long history. More than 20 years ago, at ISA Show, the world’s largest automation exhibition in the United States, I saw a company specializing in PC Control with a very eye-catching slogan “PLC die, PC-based Control immortal” (programmable controller dies, PC-based control immortal). The silhouette is deeply embedded in people’s memory. That is to say, as early as more than 20 years ago, there was a debate in the automation community in the United States about the advantages and disadvantages of PLC and PC-based control. This debate has been going on for at least seven or eight years, and the result?

H7506 PLC and PC who contend?

The American company that sang the death of PLC has disappeared after several years of tossing and turning. Of course, the company’s demise doesn’t obscure the fact that PC control is still alive and well.

Facts prove that PLC is an evergreen tree, it not only will not die, but also in the development and evolution, but also in The Times. To bring down the classic PLC “reckless” and a lot of, the first decade of this century it also experienced a PAC (programmable automatic controller,H7506 basically equivalent to PLC+PC part of the function) a round of impact, and in recent years there has been a new breed EPIC (edge programmable industrial controller), At the same time, it has the functions of PLC, motion control and industrial Internet. But PLC is still prosperous.

There are profound reasons for this. Wise people in the automation community point out that two intrinsic characteristics of PLCS are high reliability and ease of use. PLC itself is designed according to the requirements of industrial applications: to be used reliably in harsh industrial environments for a long time, with high electromagnetic compatibility (can resist all kinds of industrial electromagnetic interference, and now also requires to resist all kinds of spectrum of wireless interference), environmental adaptability (wide temperature range, high humidity, mildew, salt spray, vibration and shock resistance, etc.); To be easy to program, the general electrician, as long as the appropriate training, can write logic control ladder diagram program; Easy to maintain. These seemingly simple requirements actually require a deep industrial background.

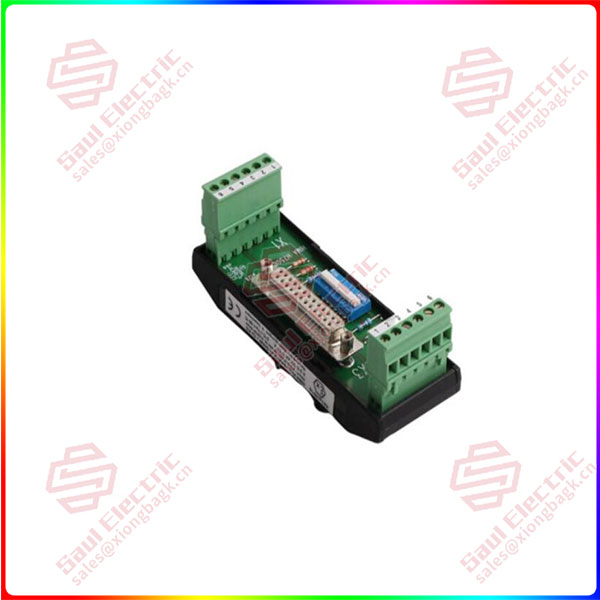

H7506

I have a lot of personal experience with this. I have seen a Japanese company’s PLC that has been in use for more than 30 years can still be used normally; I also personally dealt with a 10,000-ton horizontal press of China Second Automobile factory, which could not work normally due to the contact of the PLC output relay vibrating under high intensity vibration and impact, and then changed to another H7506 company’s PLC, which could operate normally without any reinforcement; I also solved the problem that GE PLC always broke down due to the interference of frequency converter for General Motors in Shanghai. The above examples show that in addition to the software control function, an industrial controller needs to provide I/O and power supply with high enough anti-interference, as well as strong mechanical structure and other properties.

PC control from the day it was born, is to replace the PLC software control function. Its I/O is usually plugged into the PC bus, or connected to the external I/O via RS 485. These I/ OS are no problem in the lab. However, without industrial-grade I/O and power supply to reinforce PC control, it is impossible to have the anti-interference and environmental adaptability of PLC. There is also a sensitive factor in industrial applications – cost. PC control originated in the United States and was once H7506 popular in the United States, but the last successful application was in Europe. Relying on B&R, Beckhoff and other companies to PLC PC control, so that PC control has all the advantages of PLC, provide I/O to meet various industrial requirements, solve the problem of heat and anti-interference of the power supply, can be directly installed in the harsh industrial site, with a unified engineering design operation and maintenance platform.

1 Year Warranty

1 Year Warranty