From standardization to personalized manufacturing needs for people

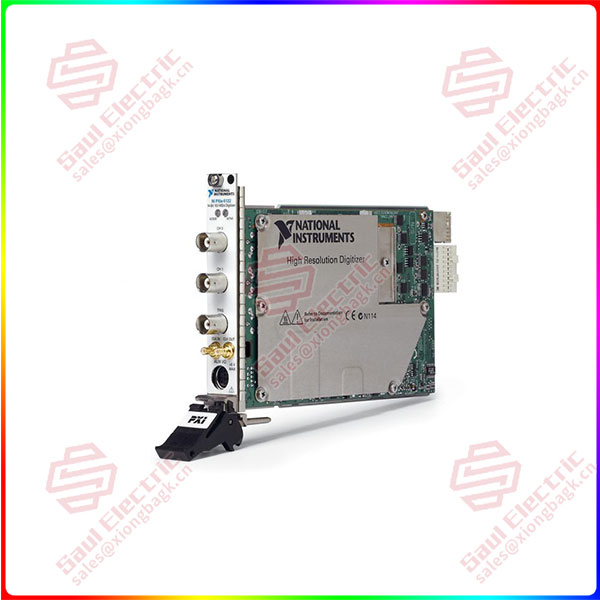

PXIE-5122 In fact, the most significant feature of the entire manufacturing industry is the gradual shift from assembly line, standardization, mass production to personalized, flexible production, in the era of Ford, “customers can want any color of the car, as long as it is black”, in the 1980s, in fact, you do not need to consider the personalized product, as long as you have a product, you can sell, in a long historical stage, Manufacturing is standardized. Therefore, they need “standardized” talents, need to be able to meet the standardized assembly line operation of people, you do not need to master too much, you only need to be like a screw, standard installation, standard operation, standard maintenance and replacement, and, in that era of the manufacturing site of the machine, are single machine, and, that is, a button switch, there is a motor drive, The process depends on experience, and the demand for talents is also that they can read drawings and operate a machine, including Taylor’s system in management science, what operating PXIE-5122 standards and standard operations are to cultivate a certain skill.

However, all manufacturing technologies, in fact, are developing in the direction of making production “flexible”, from purely manually operated machines to the use of relay logic, to PLC, to PC-based architecture control, and even to today’s edge computing, intelligent control, in fact, all the problems are because of the manufacturing changes brought about by the individual needs of products.

In order to make the machine more adaptable to production, we need to develop process modeling and simulation software to reduce the cost of physical testing and verification. In order to make the machine have more flexible adjustment ability, the automation system uses servo motors more than before. In order to solve this flexibility, from traditional rotary motors to linear motors, From linear motors to today’s maglev technologies like B&R’s ACOPOStrak and ACOPOS 6D, these are designed to address manufacturing flexibility and enable personalized production.

PXIE-5122

The trend of technology is to make manufacturing flexible

PXIE-5122 The various complex technologies we discuss today are all because today we have to face a more personalized and differentiated market, enterprises must face this challenge, design products that are more attractive to consumers, and with the development of e-commerce, the production system is subject to the volatility of order fluctuations and smaller batches. This puts forward higher requirements for the “agility” of the production system, that is, not only flexible, but also “fast!” Move it! Quickly!” In the past, e-commerce has just begun to develop, people can accept 3-7 days to receive goods, today, Jingdong self-run some products in the morning order, the afternoon can receive, behind all this is complex production, order forecasting, logistics management technical problems contained in it.

The challenge of the manufacturing industry for talent needs to become “integration”, “integration”, “complexity”, and this is engineering, the need for engineering thinking to solve the problem, we need to have a very strong engineering thinking ability, rather than just the use of a certain tool PXIE-5122 or will operate a machine people, therefore, the era of standardized talent production has obviously passed. There is an Engineering Camp program in B&R, which is a program for excellent engineers to develop engineering training with mechanical and electrical engineering, project management, software code development specifications and standards, not only skills, but how to deconstruct a mechanical and electrical object. In addition, we plan projects with strict project management process, and follow norms and standard processes to carry out innovative development, and become an engineer integrating mechanical and electrical software, including language communication, cooperation, communication, expression training, solving complex problems, using cross-border technology, which is also a replicable talent training model.

1 Year Warranty

1 Year Warranty