Equipping the factory with a data brain

PXIE-1071 In the interview, the reporter came into contact with a lot of programmers, they are often not in the office, but into the production shop. “Writing code in the workshop” is a common feature of this group of people. They install the data brain for the factory, through the deep learning of all kinds of data at the production end, based on artificial intelligence algorithms, each process can find the best solution, reduce the cost of processing…

Although the office and production workshop are only “upstairs and downstairs”, Master Yang, a worker at Chengdu New Hope Dairy, only needs to inspect machinery and equipment once a day at the end of his shift. More time, he’ll be in the control room. Only a few employees are engrossed in their computers, punctuated by the sound of keyboard tapping. “By manipulating the picture of each process section on the computer screen, you can achieve real-time and effective monitoring of production.”

PXIE-1071 People change with the position, the position also changes with people. While AI replaces some boring and uncreative jobs, it also creates many new ones. In the interview, the reporter came into contact with a lot of programmers, they are often not in the office, but into the production shop. “Writing code in the workshop” is a common feature of this group of people. Chief Information Officer, Technical Director, General Manager of Automation Division, Transparent Factory interpreter… The emergence of new titles in traditional manufacturing enterprises lets us see that in this new momentum set off by the digital economy, people engaged in new jobs jointly gather information flow belonging to the new era.

On the LCD screen of Chengdu Jiwei iot Group Co., LTD., rows of parameters dance in real time, and these data represent various links from raw materials to finished steel products. The more links, the more factors that affect the quality of the product. Chen Jun, technical director of Jiwei iot, said that the steel industry has accumulated a lot of experience after hundreds of years of development. However, experience is fragmented hidden in the “old master” head, like a black box, it is difficult to form experience sharing and large-scale reuse. What they want to do is to make these hidden knowledge explicit, and help break people’s traditional thinking frame and cognitive limitations.

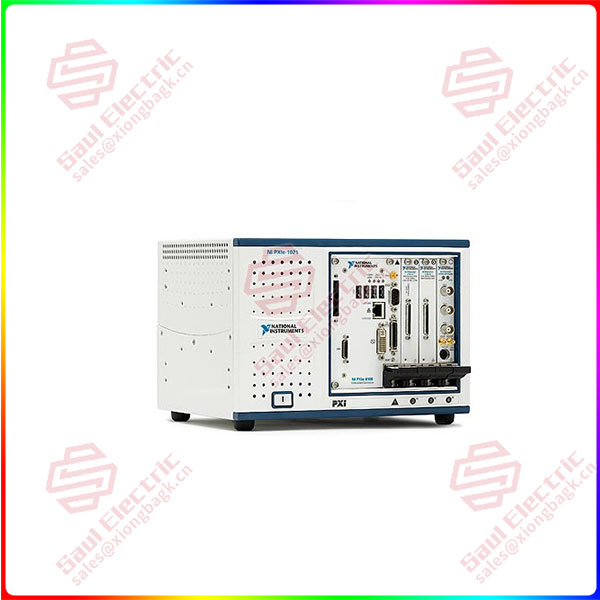

PXIE-1071

PXIE-1071 On the LCD screen of Chengdu Jiwei iot Group Co., LTD., rows of parameters dance in real time, and these data represent various links from raw materials to finished steel products

“Steel is slag”, this is an old saying in the steel production process. In order to remove some unwanted impurities from the raw material, slagging is required. Making good slag is an important guarantee to achieve high quality, high yield and low consumption in steelmaking. Today, traditional steel is equipped with industrial brains, and through deep learning of various types of data at the production end, based on artificial intelligence algorithms, each process can find the best solution to reduce the cost of processing.

“We have tens of thousands of sensors on our production line. In the past, the data collected was just put on the hard disk, and it was not useful. Now the industrial brain that we have jointly built with Ali allows industrial production data that has been silent for decades to ‘speak’ through intelligent digital technology, and we have found a ‘rich mine’.” Chen Jun said. The introduction of a set of artificial intelligence industrial brains helped enterprises save tens of millions of yuan in costs last year.

PXIE-1071 Traditional steel is equipped with industrial brains, and based on artificial intelligence algorithms, each process can find the best solution to reduce the cost of processing

More than 50 kilometers away, New Hope Dairy’s Huaxi factory has a special corridor. The corridor is not only decorated with cartoon images of cows, but also the whole process of milk from pre-treatment to packaging can be seen through the glass on both sides. Before the epidemic, there would be a transparent factory experience every day. He Rui, a field worker, does not find her job boring at all, and from time to time, she will also “part-time” work as a docent. “Similar to a tour guide, we will explain the production process and equipment of each workshop to visitors. We also play fun games to help the children learn about milk and milk safety.”

1 Year Warranty

1 Year Warranty