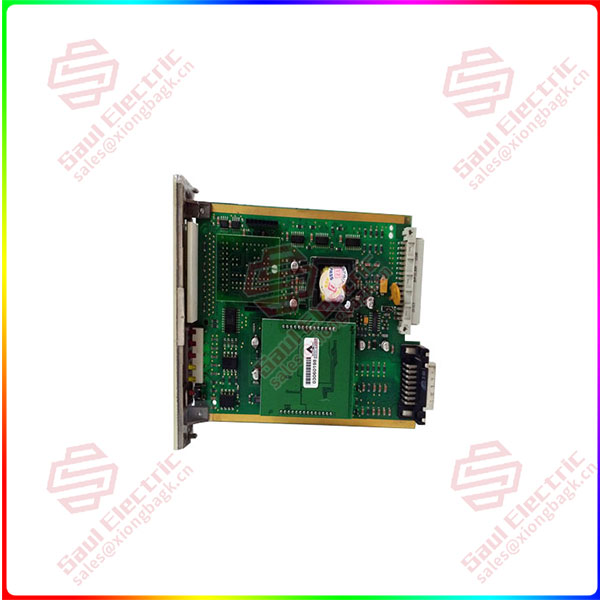

05701-A-0302 A hasty and blind upgrade can easily backfire

“The Internet can’t do everything.” Qu Xianming, director of the manufacturing Research Office of the Chinese Academy of Engineering, said frankly that new technologies such as “Internet +” and artificial intelligence play more of a catalyst role, and processing and manufacturing capacity is the fundamental and sill of manufacturing. If the industry foundation is not solid, no matter how fancy technology is difficult to play a role.

05701-A-0302 There is no doubt about the intelligent development of the manufacturing industry, but some experts pointed out that some technical capabilities are not strong, lack of talent reserves, management level is not high manufacturing enterprises, do not pay attention to the strong foundation, but a hot mind, into the tide of intelligent technology, investment is not small but little effect, this kind of biased development tendency must be vigilant.

“Smart manufacturing is not a gift, but a cherry on top.” Some experts believe that smart technology can not solve all the difficulties facing the manufacturing industry in one move. In the past, China took the path of reverse development, focusing on the complete sets of major equipment needed for people’s lives and economic development, and to a certain extent, the importance of key components and software such as chips and sensors is not enough, and the problem of weak manufacturing foundation is more prominent.

05701-A-0302 In Qu Xianming’s view, to solve the problem of manufacturing industry should also return to the manufacturing industry itself, from the core technology, parts, materials, basic manufacturing process, software and other aspects, solid foundation, focusing on the field of “jam neck”.

05701-A-0302

05701-A-0302 “For companies, we look at the whole value chain from end to end.” Wang Hongyan, chairman of the China Manufacturing International Forum and the forum organizer, Aporui Group, also believes that the quality of research and development design, process quality, production quality, procurement quality, equipment management and even quality management, personnel management quality are related to the high-quality development of enterprises. Only when the foundation is firmly established and the quality of all links is in place, intelligent technology can insert wings for the development of manufacturing industry.

05701-A-0302 Zhu Huijie, deputy director of the Intelligent Manufacturing Development Institute of the Machinery Industry Information Research Institute, pointed out that there should be three driving forces for enterprises to intelligent manufacturing: technological progress, market demand and industrial competition. “Now there are some enterprises or spontaneous, or supported by the government to carry out some digital, networked, intelligent projects, some results are good, some results are not satisfactory.” The key is what drives these projects, but also whether the company has done an assessment of its own basic capabilities and needs research.” Zhu Huijie does not recognize the blind intelligence of manufacturing enterprises.

05701-A-0302 In the early stage of intelligent construction, some enterprises did not clarify the resource base, technical capabilities and talent reserves, and the demand was not clear and detailed. In this case, although the enterprise recognizes the rapid changes in the market and the breakthrough of technology, it also clearly feels the competitive pressure, but the foundation is not solid enough, and blind intelligence is difficult to achieve the expected effect in the short term, and even easy to backfire, increasing the financial burden of the enterprise.

1 Year Warranty

1 Year Warranty