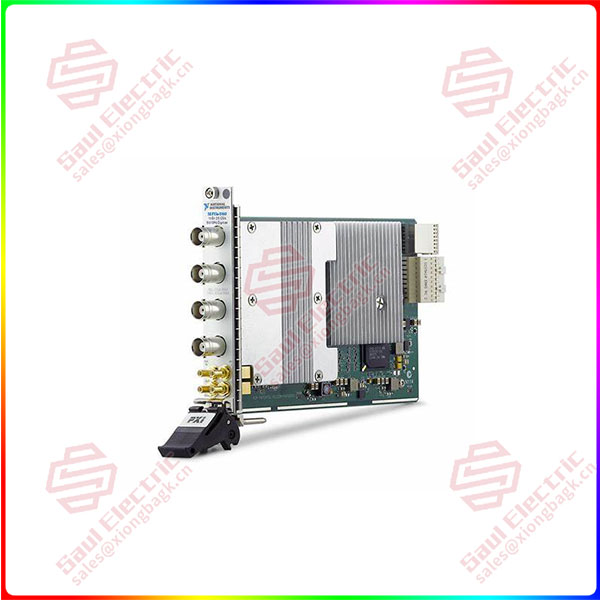

PXIe-5160 The reporter learned from the Ministry of Industry and Information Technology on the 25th that the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Finance and other nine departments jointly issued the Work Plan for the Digital transformation of the Raw material Industry (2024-2026) (hereinafter referred to as the “Plan”) to promote the digital transformation of the raw material industry, accelerate the promotion of new industrialization, and build a manufacturing power.

PXIe-5160 The raw material industry is the foundation of the real economy and the basic industry supporting the development of the national economy. As a typical process manufacturing industry, raw material industry mainly has three characteristics: resource and energy intensive, complex process mechanism and strong production continuity.

PXIe-5160 The digital transformation of raw material industry refers to the use of digital technologies such as artificial intelligence, 5G, and industrial Internet to carry out integrated innovation and transformation and upgrading in all aspects of material research and development, production and manufacturing, enterprise operation and management, logistics and warehousing, industry operation regulation, coupling and coordination, and upstream and downstream collaboration, so as to drive the business transformation of the whole industrial chain with industrial digitalization. Accelerate the promotion of industry quality upgrading, cost reduction and efficiency, green and safe development.

“China has the dual advantages of being a manufacturing power superimposed on a network power, and has built the world’s largest and most complete industrial system and the most technologically advanced and widely covered information and communication infrastructure. It is in a period of major opportunities to promote high-quality industrial development through digital transformation.” The responsible person of the Ministry of Industry and Information Technology said.

PXIe-5160

PXIe-5160 The person in charge introduced that the added value of raw material industry accounts for about 30% of the added value of industries above scale in China, and is the main force to promote the digital transformation of manufacturing industry. In recent years, the digital transformation of China’s raw material industry has continued to go deep, and some leading enterprises in the industry have reached the international leading level, but they still face problems such as insufficient understanding of digital transformation, large differences in the basis of digital transformation, high difficulty in modeling and simulation, insufficient integration and application of digital technology, and shortage of compound talents.

PXIe-5160 The “Plan” proposes that by 2026, the digital transformation of the raw material industry will make important progress, key enterprises will complete the diagnosis and evaluation of digital transformation, and the level of ubiquitous perception of production factors, independent regulation of manufacturing processes, and optimal decision-making of operation management will be greatly improved. Specifically, the application level has been significantly improved, creating more than 120 typical scenarios for digital transformation, cultivating more than 60 benchmark factories for digital transformation, and forming a number of benchmark enterprises for digital transformation; Indicators such as the numerical control rate of key processes in key industries and the penetration rate of digital R & D and design tools have been significantly improved, and enterprises with digital transformation maturity level 3 and above have been increased to more than 20%. The support capacity has been significantly enhanced, a number of key core technologies urgently needed for digital transformation have been broken through, and a number of advanced and applicable digital transformation standards and specifications have been revised; Promote and apply more than 100 excellent products, and cultivate 100 excellent system solution providers. The service system has been improved, with the construction of 1 big data center for new materials, 4 digital transformation promotion centers for key industries, 4 manufacturing innovation centers for key industries, more than 5 secondary nodes for industrial Internet identification analysis, and more than 6 industry-level industrial Internet platforms.

PXIe-5160 The plan has 14 tasks in 4 aspects, including strengthening the intelligent foundation, strengthening the construction, deployment and popularization of intelligent equipment, computing facilities and model algorithms in key industries; Cultivate digital transformation benchmarks, and create a number of digital transformation typical scenarios, benchmark factories, smart mines, and benchmark enterprises; Strengthen the supply of technological innovation, cultivate a number of products and system solutions for key industries, and build innovation centers for raw material industry and manufacturing in different industries; Strengthen the drive of artificial intelligence, catalyze a number of low-cost high-value artificial intelligence products and solutions, and build a general large model for subdivided industries.

1 Year Warranty

1 Year Warranty