Description

概观

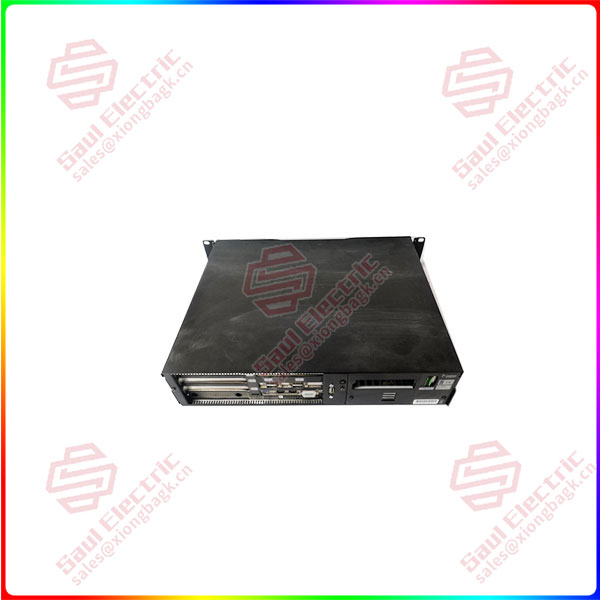

Essential details:D201126L D200137 Control Plc Module

The “D201126L Plc control module “appears to be a PLC (Programmable Logic Controller) control module of a specific model or identifier. A PLC is a digital electronic system used in industrial automation to control machinery or processes. It can be programmed to perform various tasks, such as monitoring the status of input devices (such as sensors), performing logical decisions based on those inputs, and controlling output devices (such as motors, valves, etc.).

“D201126L” may be a specific model or batch number for this PLC control module. Different manufacturers may use different naming and numbering systems, so this logo may be unique to a particular manufacturer.

The main functions of PLC control module include the following aspects:

Logic control: The most basic function of PLC is to perform logical operations, such as AND (AND), OR (OR), NOT (NOT), etc., for controlling the switch and sequential operation of the equipment.

Sequence control: PLCS can be programmed to manage the sequential operation of equipment, for example, to control the start, run and stop sequence of a production line.

Timing and counting: The PLC has built-in timers and counters, which can be used to perform timing tasks and counting tasks, such as controlling the running time of the equipment or the production quantity.

D200137

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@saulcontrol.com

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

D201126L D200137 Control Plc Module

Data processing: PLCS can receive and process data from sensors, operator interfaces, or other control systems and perform complex control logic based on these data.

Communication: PLCS usually have communication capabilities and can exchange data with other PLCS, human machine interfaces (Hmis), computers or other industrial equipment through different communication protocols (such as Modbus, Ethernet/IP, Profinet, etc.).

Remote monitoring and control: Through the communication function, the PLC can be connected to the remote monitoring system, so that the operator can remotely monitor the status of the equipment and control the operation of the equipment.

Fault diagnosis and protection: The PLC can monitor the operating status of the equipment and trigger alarms or take protective measures when an anomaly or failure is detected, such as shutdown, switching to safe mode, etc.

Extensibility and flexibility: PLCS are usually designed to be modular, and modules can be added or removed as needed to expand their functionality. In addition, the PLC programming flexibility is very high, you can change the control logic by modifying the program to adapt to different application needs.

In summary, the main function of the PLC control module is to provide a programmable, reliable, flexible and easy to maintain control platform for industrial automation and control tasks.

1 Year Warranty

1 Year Warranty