Continuous intelligent investment to help 100 billion Xingfa

0190-34055 The successful operation of the smart factory project for caustic soda production in Inner Mongolia Park of Xingfa Group provides a sample for the construction of a smart factory for the autonomous operation of chlor-alkali industry. The i-OMC system connects all elements of enterprise production equipment, process and data in a digital way, and the comprehensive utilization rate of data exceeds 80% in terms of asset appreciation. In addition, based on the technical architecture of “factory operating system + industrial APP”, plug-in apps such as production management and environmental safety management are deployed on a unified data base, and integrated applications are formed with 0190-34055 whole-plant video surveillance, unmanned inspection system, industrial salt intelligent unloading and collection system, automatic online analysis system, and circulating water intelligent temperature control system.

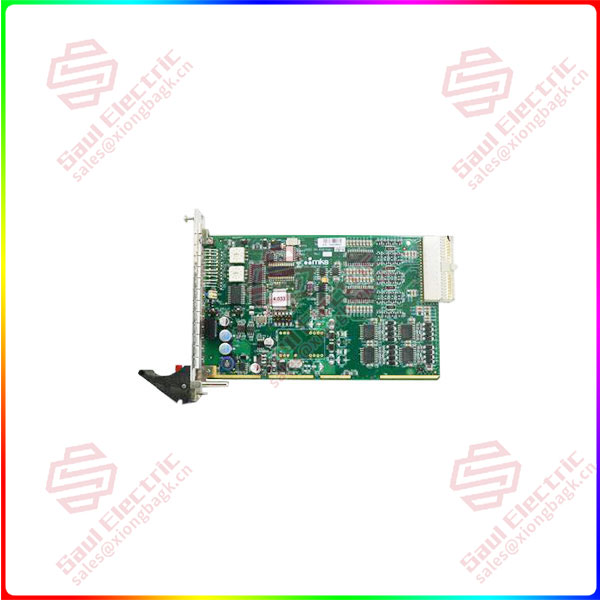

0190-34055

Help enterprises achieve transparent production process, refined operation management, intelligent decision support, and ensure that enterprises achieve quality, cost reduction, efficiency, safety, and low-carbon operation excellence.

0190-34055 Yang Kunming, chairman of Inner Mongolia Xingfa, said: “Through continuous investment in digital intelligence, we have truly achieved a rare domestic unmanned inspection, unmanned operation, unmanned record of the ‘three no factory’, effectively solve the problem of regional labor difficulties, recruitment difficulties, and establish a safe, environmental protection, stable, refined production and operation control system, to help the strategic development of 100 billion Xingfa.”

1 Year Warranty

1 Year Warranty