Industrial automatic control system device manufacturing refers to the manufacturing of industrial computer control systems, detection instruments, actuators and devices used to measure and control variables such as temperature, pressure, flow, level or parameters such as object position, tilt, rotation in the continuous or intermittent production and manufacturing process.

China’s industrial automation and industrial control market or at the bottom of the cycle

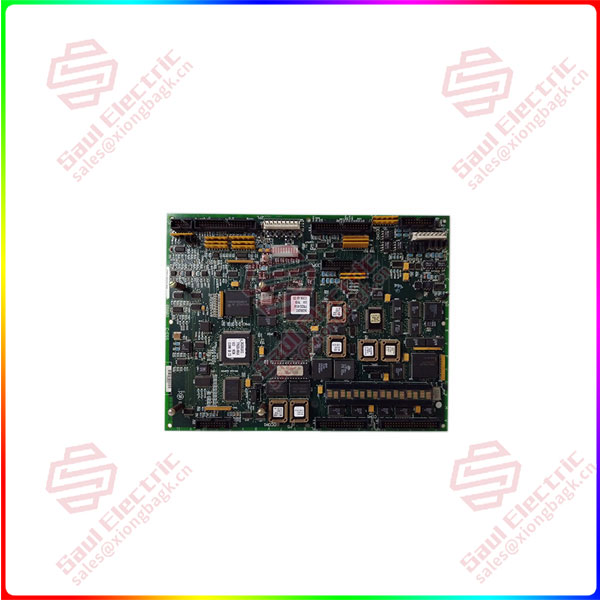

DS200LDCCH1ANA According to the “China Automation and intelligent Manufacturing Market White Paper” released by China Industrial Control network, China’s automation and industrial control products are mainly divided into drive systems, feedback systems, control systems, execution systems, motion systems and others.

According to the statistics of the “White Paper on China’s Automation and intelligent Manufacturing Market” released by China Industrial Control Network, the size of China’s automation and industrial control market showed a fluctuating upward trend from 2004 to 2018, with a clear cyclical trend. The market size has increased from 65.2 billion yuan in 2004 to 183 billion yuan in 2018, with a compound annual growth rate of 7.65%; In 2019, the scale of China’s automation and industrial control market reached 186.5 billion yuan, and the scale growth rate continued to decline, and the industry as a whole was at the relative bottom of the cycle.

Figure 2: Market size and growth of China’s Industrial automatic control system device manufacturing industry from 2004 to 2019 (unit: 100 million yuan, %)

The market share of OEM field exceeds that of project field

China’s automation and industrial control downstream market is mainly divided into OEM field and project field.

The downstream OEM market mainly includes: DS200LDCCH1ANA textile machinery, machine tools, plastic machinery, rubber machinery, food machinery, packaging machinery, printing machinery, lifting machinery, HVAC, mining machinery, elevator, paper machinery, electronic manufacturing equipment, construction machinery, transportation, power equipment, medical equipment, wind power and so on.

The downstream of the project market mainly includes: petrochemical, chemical, metallurgy, municipal, public facilities, oil and gas, building materials, mining, paper, electric power, automobile.

From 2009 to 2018, the OEM market share continued to rise. In 2009, the OEM market share increased to 42.6%, and in 2018, the market share rose to 50.1%, surpassing the project field. In 2018, the market share of project-based sector was 49.9%.

DS200LDCCH1ANA

The automation and industrial control market is mainly distributed in East and South China

According to the statistics of the “China Automation and Intelligent Manufacturing Market White Paper” released by China Industrial Control Network, 2018 China’s automation and industrial control market is mainly distributed in East China (Guangdong, Guangxi, DS200LDCCH1ANA Hunan, Hubei, Henan, Hainan) and South China (Shandong, Anhui, Jiangsu, Shanghai, Zhejiang, Jiangxi, Fujian). The market share was 43.3% and 25.8% respectively; The market share in North China (Beijing, Tianjin, Hebei, Shaanxi, Inner Mongolia) and Northeast China (Heilongjiang, Jilin, Liaoning) was 12.2% and 7.9%, respectively; The northwest (Shaanxi, Ningxia, Gansu, Qinghai, Xinjiang) and southwest (Sichuan, Chongqing, Guizhou, Yunnan, Tibet) regions have smaller market shares, 6.5% and 4.3% respectively.

In 2019, the market shares of South China, Southwest, Northwest and North China increased, accounting for 27.0%, 6.8%, 4.5% and 12.4% respectively. East China and Northeast China saw a decline in the market, with 41.6% and 7.8% respectively.

Feedback, control and drive systems are the three major markets for automation and industrial control

According to Industrial control network data, the three most important market segments in China’s automation and industrial control market in 2019 are feedback systems, control systems and drive systems, accounting for 24.3%, 22.0% and 19.8%, respectively.

In terms of feedback systems, the market share showed a fluctuating upward trend from 2009 to 2019, and the market share of feedback systems reached 24.3% in 2019, the highest value in recent years.

In terms of control systems, since 2015, the share of control systems has continued to rise, and the market share of control systems has risen to 22.0% in 2019.

In terms of drive systems, the market share of drive systems from 2009 to 2017 continued to decline, and the market share of drive systems in 2017 was 19.1%; The market share of drive systems recovered in 2018-2019, reaching 19.2% in 2018 and further increasing to 19.8% in 2019.

The above data comes from the Prospective Industry Research Institute “China Industrial automatic control system device manufacturing industry production and sales demand forecast and transformation and upgrading analysis report”, while the prospective industry Research Institute provides industrial big data, industrial planning, industrial declaration, industrial park planning, industrial investment and other solutions.

1 Year Warranty

1 Year Warranty