Cognex’s latest In-Sight SnAPP vision sensor, powered by AI and image analysis technology, is more comprehensive and powerful than traditional laser sensors, providing superior accuracy and powerful performance for a variety of inspection tasks, ensuring accurate and reliable inspection results.

Let’s delve deeper into the four benefits of In-Sight SnAPP vision sensors and see how they stand out from the crowd!

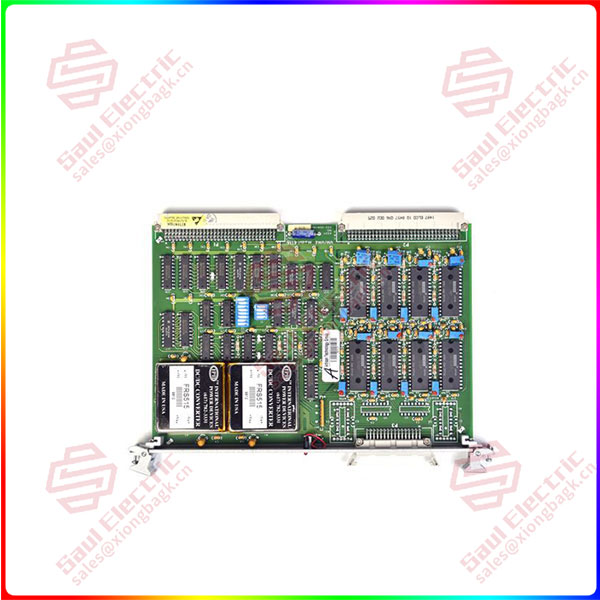

VMIVME-4116 From single point to multipoint detection

Expanded detection possibilities

In contrast to the single-point detection of other sensors, the In-Sight SnAPP vision sensor utilizes image-based planar detection and AI technology to achieve multi-point detection, quickly handling a range of error-proof tasks such as anomaly detection and binary classification. It does not require a precision fixture during installation, and the user can freely move and adjust the boundary box to determine the image area that needs to be detected, not only expanding the possibility of detection, but also providing more accurate detection results.

* The limitations of traditional sensors versus the advantages of In-Sight SnAPP

Multitask switching

Easy detection automation

VMIVME-4116 In-sight SnAPP vision sensors can quickly switch between different inspection application scenarios and flexibly respond to changes In target detection objects on the production line, making them ideal for production lines with variable inspection tasks. The user can adjust the parameter adjustment through the intuitive interface, and can switch between different applications at any time, ensuring that every test is accurate. A single device enables multiple detection without hardware replacement, effectively reducing deployment costs.

VMIVME-4116

Support image storage

NG product analysis and optimization

In-Sight SnAPP vision sensors support image storage and facilitate the collection of NG product data for later analysis. By comparing the images of OK and NG products, users can quickly locate problems in the VMIVME-4116 production process, providing a strong basis for optimizing the production process and improving product quality.

Multiple communication interfaces are supported

Easy to use and efficient collaboration

In-Sight SnAPP vision sensor built-in industrial Ethernet communication protocol, can be easily integrated with PLC, simple to use, can achieve real-time transmission and sharing of data between different devices, strengthen the information transmission and interaction between the same production line equipment, so as to work together to improve the efficiency and intelligence of automated production system

In-Sight SnAPP vision sensors are powerful and easy to use, and powered by AI technology, with four significant advantages, it sets a new benchmark for vision sensors and helps new manufacturers quickly automate inspection.

1 Year Warranty

1 Year Warranty