Navigable in complex environments

With new 3D vision technology, the MiR1200 pallet lift truck is able to easily meet the challenges and help enterprises solve the problems of resource-intensive material handling. Especially in today’s increasingly tight labor force, enterprises are vulnerable to complex work environments, so the need for automation is particularly urgent.

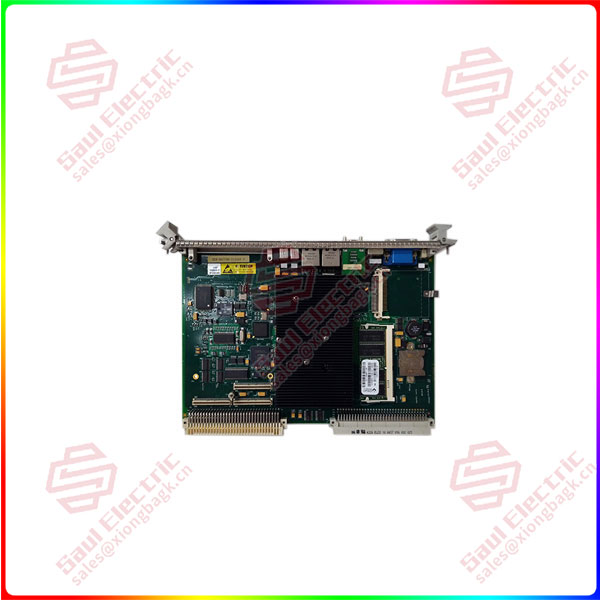

VMIVME-7700 The MiR1200 pallet lift can adjust the path in real time to avoid obstacles, such as ground debris or overhead obstacles. The AMR leverages the GPU built into Nvidia’s Jetson AGX Orin module and multiple processors for full stack acceleration, capable of processing massive amounts of data from numerous cameras and lidar in real time. In addition, it is able to navigate flexibly in small Spaces, without the need to retrofit existing infrastructure, which can significantly improve logistics efficiency and ensure the on-time delivery of pallets.

Jean-Pierre Hathout, President of MiR, said: “The MiR1200 pallet lift truck is rugged and capable of handling complex factory environments and responding to multiple automation challenges. In the design of this robot, we took full advantage of MiR’s accumulated expertise in software.VMIVME-7700 In 2022, MiR and AutoGuide, also part of the Teredad Group, jointly developed and developed a breakthrough technology in heavy-duty AMR. At the same time, together with our partner Logitrans, who has more than 80 years of experience in the material handling industry, we have developed a robust three-wheel drive system that provides reliable power support for the new product.”

VMIVME-7700

Safety first

Jean-Pierre Hathout, President of MiR, said: “The MiR1200 pallet Handling AMR is designed not only for speed and efficiency, but also for safety. The concept of ‘safety’ is embedded in every MiR product. “The MiR1200 Pallet Handling AMR meets the latest product safety standards, including ISO3691-4, and integrates the safety features of multiple sensor platforms, making it a safer solution than conventional forklifts, pallet handling forklifts and manual pallet handling forklifts.”

MiR1200 pallet lift truck main performance:

Artificial Intelligence inspection technology from Nvidia: Trained on more than 1.2 million real and synthetic images, it enables fast and accurate pallet inspection.

• High battery capacity and fast charging: The MiR1200 pallet-handling AMR has a 1:14 charging rate and time-sensitive charging convenience, which can meet the requirements of 24-hour uninterrupted operation.

• ISO safety compliance: Designed to comply with the latest product safety standards, including ISO 3691-4, to ensure safe operation of AMR in a variety of work environments.

•3D sensor detection of obstacles: Combining LiDAR and 3D VMIVME-7700 vision technology to accurately identify obstacles and ensure accurate and safe placement of pallets.

• Strong mobility: The IP52 protection class is equipped with sturdy wheels that allow for free movement on various ramps or road environments.

The MiR1200 pallet lift truck relies on artificial intelligence technology to effectively solve the transportation problems of enterprises in complex and dynamic environments. The launch of the new products also marks that MiR is gradually becoming a comprehensive solution provider in the field of autonomous material handling in more factories and warehouses, and is committed to providing customers with efficient and intelligent logistics solutions to help enterprises improve transportation efficiency and realize intelligent upgrading of production processes.

1 Year Warranty

1 Year Warranty