Today, in the face of the growing climate challenge, more and more multinational companies are taking a more active look at their sustainable development goals and capabilities. Groupe Renault, renowned in the global automotive industry, is one such leading company actively promoting green goals. As a leader in the circular economy of the automotive industry, Groupe Renault began to practice the circular economy approach in its operations as early as 2000. Over the years, Groupe Renault has also been continuously examining the entire life cycle of its operations and constantly seeking new sustainable development opportunities.

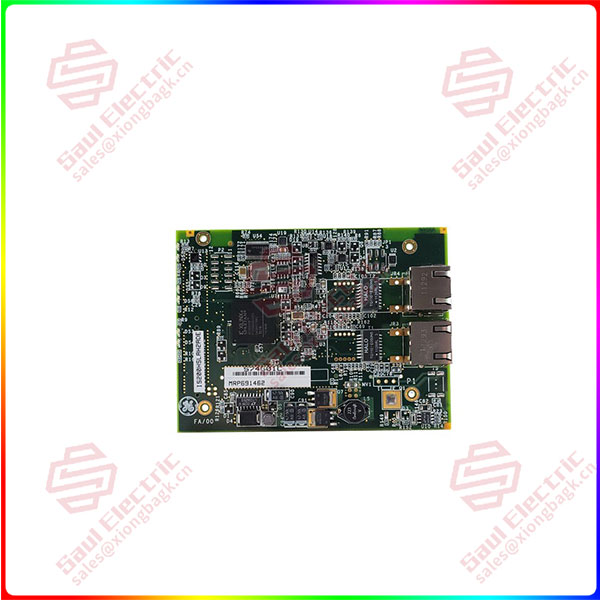

IS200HSLAH2ADE Green, safety and reliability: circular economy challenges for the Frings Plant

Today, Grouper Renault has set its sights on sustainable upgrades at its Frings plant in France. Groupe Renault has been working to develop convenient, sustainable and zero-carbon mobility solutions at the plant. Renault now aims to transform the Frings plant into Europe’s first dedicated circular economy plant for the production of cars, and to achieve a negative carbon balance by 2030.

IS200HSLAH2ADE

In order to achieve this goal, Grougroup Renault began to focus on improving all aspects of the Frings plant, from the power distribution system to the recycling of resources, to reduce the plant’s CO2 emissions as much as possible. In terms of the plant’s power distribution system, sulfur hexafluoride, a greenhouse gas widely used in power distribution equipment, has become an important breakthrough for the plant to promote green upgrades.

For a long time, sulfur hexafluoride has been widely used in power distribution equipment with excellent arc extinguishing and insulation properties, as well as good chemical stability. But in the face of the growing climate challenge, the impact of this gas on global warming is becoming IS200HSLAH2ADE increasingly difficult to ignore. The greenhouse gas effect of sulfur hexafluoride is 25,200 times that of carbon dioxide. Finding a greener alternative would go a long way towards meeting Frings’ circular economy goals.

Of course, the recycling plant has to take into account not only the need to reduce greenhouse gas emissions, but also the challenges such as power reliability and cybersecurity that cannot be ignored. Once the power is lost, it will not only lead to safety risks, but also interrupt the manufacturing process, resulting in damage to the vehicle being built and delayed delivery. In the event of a cyber intrusion, the operation of the factory is likely to face a devastating blow.

1 Year Warranty

1 Year Warranty