Industrial software is becoming a hot topic in China’s manufacturing industry, whether it is the manufacturing end, equipment manufacturing, automation fields, everyone is beginning to realize the importance of software, as well as the knowledge behind the software, basic theoretical research, engineering practice, the importance of data. This is an industrial collective action based on the value cognition of knowledge, engineering, innovation, service and talent. This heralds a collective awakening in the industry – putting us on track for an even more significant reinvention of competitiveness.

Industry needs are changing

Digital transformation and high-quality development

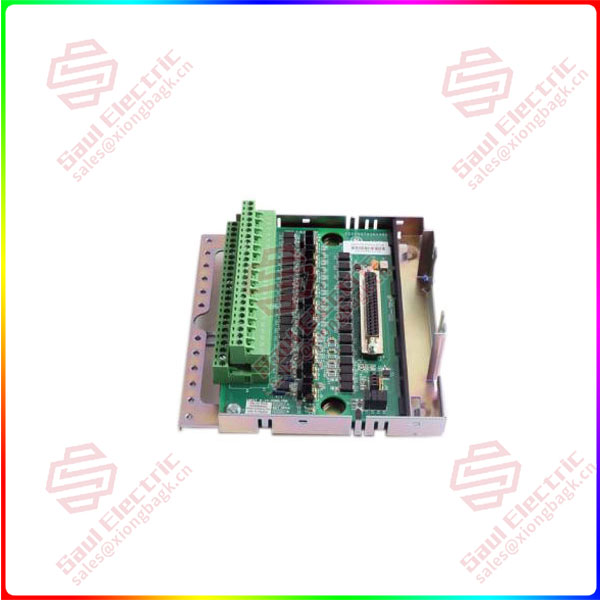

IS230SNCIH6A

The transformation of enterprises should move the business from low-end to high-end, from low value-added to high value-added, from fast money to sustainable development. At the national level, high-quality development is advocated, and enterprises should also be transformed to the road of more competitive, responsive to change, and differentiated competitiveness.

Figure 1- The transformation of the enterprise lies in the extension of high value added from low end to sustainable

Digitalization for enterprise transformation, first of all, is to replace the uncertainty of people in manufacturing with the flexibility of digitalization, and convert human knowledge and experience into reusable software. Secondly, it is necessary to have the ability to respond to market changes, to digitize manufacturing, because digitalization has the greatest flexibility, through software definition can achieve flexible changes in production lines, industrial interconnection, digital twins, edge computing are to solve these problems. Third, digital transformation pays more attention to enterprises with talents and service capabilities in intelligent technology, because professional segmentation and collaborative community of interests to cope with competition has become inevitable.

Application complexity and specialty complexity

IS230SNCIH6A

Before the 1980s, the manufacturing industry was in the production of large-scale standard parts, fixed mechanical structure, and the application of a machine can be controlled through PLC logic control and electrical transmission mechanism. In those days, an electrical engineer could easily control the programming of a machine. Even after the 1990s, as the complexity of the material types of the machine increased, there was more demand for control processes, and a large number of servo motor applications in printing, plastics and other fields also made the application of multi-axis synchronization, electronic cams became more common, but even at this stage, electrical engineers can still control the program of a machine – to use IT industry terminology, This is known as a “full stack engineer”, that is, a single engineer can control the application design and testing of the entire machine.

IS230SNCIH6A

Figure 2- The process of automation and intelligence in equipment manufacturing industry

As machines become more complex, the boundaries of automation continue to expand, from the ladder diagram of the past to the algorithm engineer, from only understanding logic to complex process algorithms. From variable frequency drives to a large number of servo systems, as well as CNC and robot applications, and even today’s mechatronics such as B&R’s ACOPOStrak flexible conveying technology, machine vision, and defect analysis and optimization applications using machine learning and deep learning.

There is no longer a full-stack engineer, but the need for multi-professional collaboration, the collaboration of different teams, in order to meet the overall integration needs from the machine to the factory, which makes “planning”, “integration” of such complex engineering problems experts become more urgent demand.

Customization, extending to applications and services

In 30 years ago, the machine still belongs to the seller’s market, the standard model is there, however, today, this does not exist, every customer’s machine will be different, even a customer’s different factory/workshop, this year and last year’s difference – this change comes from the pressure of the market, the difference in the market segment, but also from the need for differentiated competition.

The personality of the end market is transmitted to the personalized production of manufacturing enterprises, and for the machine, it becomes how to respond to change. This demand is transmitted to the automation industry, which requires modular software and hardware to quickly build application systems.

IS230SNCIH6A

This requires automation companies with the ability to build applications quickly, including the modular design of software, and experienced electromechanical engineers – because test validation also requires experience in order to shorten the cycle time. Experience can reduce this process of exploration.

The ability of application software development and engineering consulting and implementation services will inevitably become the most important competitiveness of automation enterprises in the future. Because the difference in hardware is not large, and horizontal scientific and technological resources are not scarce. However, talent, industry knowledge, professional services – can form the soft power of automation enterprises.

What are the automation software and services?

The process of the industry, Know-How, is encapsulated as software modules, which is the essence of industrial software – the reuse of knowledge. The service is for the whole life cycle of the equipment, from the early planning and design of the machine consulting, program development, personnel training, remote operation and maintenance, upgrade and transformation of the whole process.

1 Year Warranty

1 Year Warranty