As an important part of automated logistics system, automated sorting system has been widely used in industrial production and commercial trade. Sorting system in accordance with the pre-set instructions for the goods to be sorted, and the sorted goods delivered to the designated location, mainly to achieve the goods according to certain rules to pick, classify or concentrate, is the enterprise to complete the production, support the return, improve the return of the preparatory work, is the central link of the express business.

Improve sorting efficiency and solve the capacity bottleneck of logistics enterprises

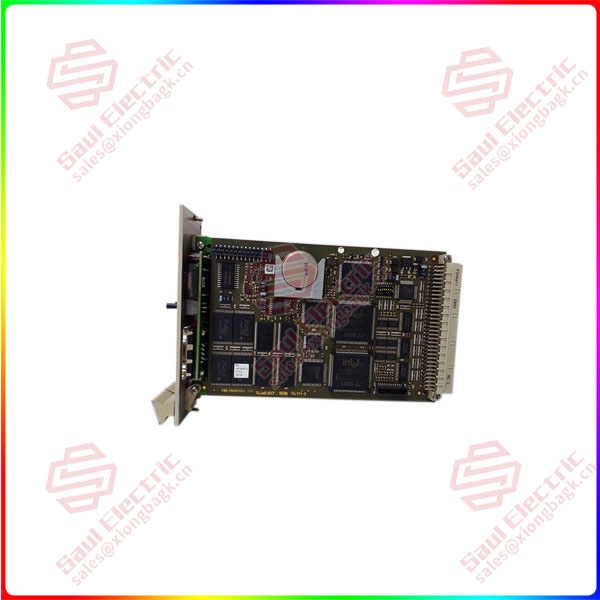

F8652X Traditional sorting centers are purely manual sorting or semi-automated sorting assisted by conveyor belts. The traditional manual sorting efficiency is low, in the face of “double 11”, “double 12” and other business peaks, the traditional manual sorting can not complete the sorting of the surge of goods in a short period of time, so express companies often appear “warehouse explosion” phenomenon. The sorting efficiency of the automated sorting and conveying system is high, so that the express company can expand the sorting capacity without increasing the labor, and the sorting is no longer a factor limiting the single volume of the express business, even in the face of seasonal or sudden market, it can also be resolved by increasing the number of daily deliveries, which can effectively respond to the peak of the express business and open the ceiling of the business volume of the express company.

Reduce operating costs and improve user experience

The automated sorting and conveying system can effectively reduce the labor costs, land costs, sorting errors and costs caused by express delivery damage. With the gradual disappearance of the demographic dividend, the labor costs required for sorting are still on the rise, and in the traditional e-commerce peak season such as “Double 11”, there may be a sudden rise in costs caused by “labor shortage”, which can be solved by automation to cope with the increasing comprehensive labor costs. In recent years, major express delivery enterprises have gradually expanded the application scale of automatic sorting systems, and the F8652X transit operation cost has also been greatly reduced.

Enable automated device-based big data collection and processing

Logistics sorting automation helps logistics enterprises realize big data collection and processing based on automated equipment. As the key link of the whole process, the sorting link of the transportation center needs to collect and distribute a large number of packages, and collect and transmit the information of each package. Therefore, from the perspective of the basic logistics process, the automation of the sorting link is crucial to the collection and processing of big data. The informatization effect of logistics enterprises also depends on the popularity of automated sorting equipment, and the comprehensive automation of logistics sorting is a key factor for logistics enterprises to achieve big data collection and processing.

F8652X

Advantages of automated sorting systems

1. Improve sorting efficiency

F8652X The automatic sorting system has high sorting efficiency and can sort items in large quantities and continuous operations. The system is not affected by climate, time, place and other factors, the use of flow operation, can make the operation free from the influence of human factors, as long as properly maintained, can be continuous sorting for hundreds of hours, high sorting efficiency, can be sorted tens of thousands of goods per hour, the efficiency is generally tens of times that of manual.

2, reduce sorting errors

Low sorting error and high accuracy. As long as the instructions entered by the control system are accurate, the error rate of the sorting system will be extremely low. Compared to the high error rate of normal manual operations, the automated sorting system can reduce the error rate to 0.01%.

3, reduce labor costs

The automated sorting system can basically realize unmanned operation. F8652X One of the reasons for the emergence of logistics automated sorting system is to reduce the labor intensity of employees, improve production efficiency, reduce costs, and improve corporate profits. With the upgrade of the system, the advanced logistics center can achieve “black light” operation, so that the sorting process basically does not require personnel participation, and the use of personnel is only before and after the sorting is completed, or for the maintenance of the sorting system.

1 Year Warranty

1 Year Warranty