On April 9, the world’s first 300 MW pressurized gas energy storage power station (set), Hubei Yingcheng 300 MW pressurized gas energy storage power station demonstration project was successfully connected to the grid for the first time, creating three world records of single power, energy storage scale and conversion efficiency, and dozens of international first and global first breakthroughs in 6 industries . The project was selected in the “Third batch of energy field first (set) major technical equipment (project) List” issued by the National Energy Administration. Hollysys provided the 300MW unfired compressed air expander DEH, ETS and ATC control systems for the project.

NTCF22 The project is a national new energy storage pilot demonstration project, the use of waste salt mine as a gas storage, energy storage can be 8 hours a day, 5 hours of energy release, annual power generation of about 500 million KWH, will effectively improve the regional power grid peak load capacity, promote the grid to absorb more wind power, photovoltaic and other new energy. Through joint technical research and experimental demonstration, the key core technology and equipment of the project have achieved 100% localization, overcoming many problems such as process system integration, underground gas storage construction, and key equipment research and development.

NTCF22

The successful grid-connection of the project is a milestone event of a new type of energy storage project, which verifies the reliability, innovation and extensibility of the large-capacity, high-efficiency and ultra-long-term “compressed gas energy storage system solution”, provides a demonstration for the commercial application of large-scale new energy storage technology, and marks that China’s high-power compressed gas energy storage technology has reached the world’s leading level.

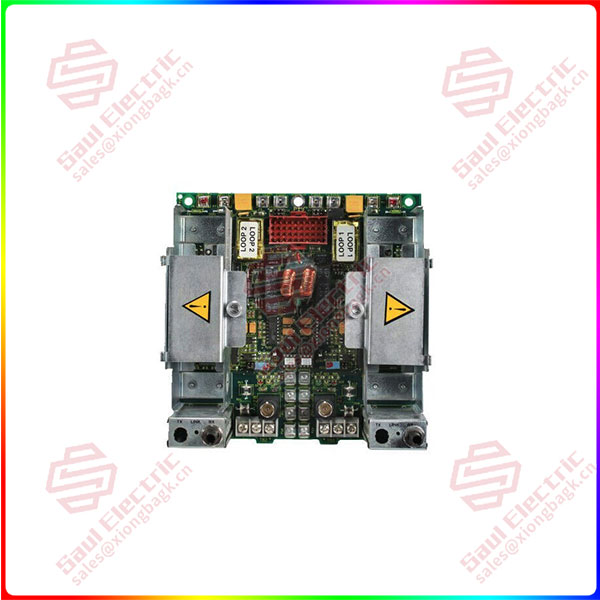

NTCF22 The core part of the project is the expansion machine control system using Hollysys’ K-series hardware, the expansion machine speed control system BTC station uses K-CU02 controller, the emergency shutdown ETS system uses K-CU03 high-speed, high reliability and high performance controller, and the ATC control station uses K-CU02 controller. The project plans to store energy for 8 hours and release energy for 5 hours per day. In order to adapt to the unit’s frequent start-stop working conditions, the expansion machine control program has designed a one-click start-stop function of APS. The unit can operate from shock rotation, grid-connected to load with one-click operation. The system has the advantages of simple operation, high reliability, strong security, easy to start and stop.

The project innovatively integrates Hollysys’ various fist products perfectly, confirming the high compatibility and operability between the products of Hollysys.

Hollysys personnel dare to work hard, contribute their own strength in the new energy storage, and contribute ideas for the construction of China’s new power system and the realization of the “double carbon” goal.

1 Year Warranty

1 Year Warranty