Description

Overview

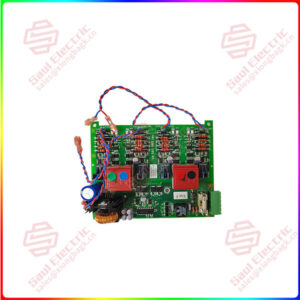

Essential details:ISH070/60017/0/1/00/0/10/10/00 SERVO MOTOR

servo motor (servo motor) is an engine that controls the operation of mechanical components in a servo system, and is a supplementary motor indirect transmission device. This motor can convert the voltage signal into torque and speed to drive the control object. Servo motor has the characteristics of small electromechanical time constant, high linearity, and its rotor speed is controlled by the input signal, which can respond quickly. Therefore, the servo motor is often used as an executive element in the automatic control system, and its position accuracy is very accurate.

Servo motor is mainly divided into DC and AC servo motor two categories, its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases with the increase of torque. Servo motors have a wide range of applications in many fields, including but not limited to industrial production, robotics, aerospace, medical equipment and the automotive industry. In these areas, servo motors provide precise, stable and efficient motion control that improves production efficiency, product quality and system performance.

SM-100-40-080-P0-45-S1-B0

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

ISH070/60017/0/1/00/0/10/10/00 SERVO MOTOR

The working principle of the servo motor is mainly based on the feedback control system, which controls the position, speed and acceleration of the motor through accurate input signals. Here are the detailed steps on how it works:

Control signal input: First, input the control signal to the controller of the servo motor. This signal can be in the form of a voltage, current, or pulse and represents the desired motor position, speed, or acceleration.

Control signal processing: After receiving the input signal, the controller will process it and convert it into a signal suitable for driving the motor. This process may involve signal amplification, filtering, conversion and other steps.

Drive motor rotation: The processed signal is sent to the driver of the servo motor, which controls the current and voltage of the motor according to the signal, thus driving the motor rotation. The rotation Angle, speed and direction of the motor are precisely controlled by the input signal.

Feedback system operation: The servo motor is equipped with sensors (such as encoders) for real-time measurement of the motor Angle or speed. The sensor returns the measured data to the controller as a feedback signal.

Error calculation and adjustment: The controller compares the feedback signal with the input signal to calculate the error. Then, based on this error, the controller adjusts the output signal to reduce the error and make the motor more precisely reach the desired position or speed.

Continuous adjustment and optimization: This process is continuous, and through continuous comparison and adjustment, the servo motor can achieve precise control of position, speed and acceleration.

Servo motor has the characteristics of small electromechanical time constant and high linearity, which can quickly respond to the change of input signal. This makes servo motors ideal for applications that require high precision, high speed and high responsiveness, such as robotics, automation equipment, CNC machine tools, etc.

1 Year Warranty

1 Year Warranty