Description

Overview

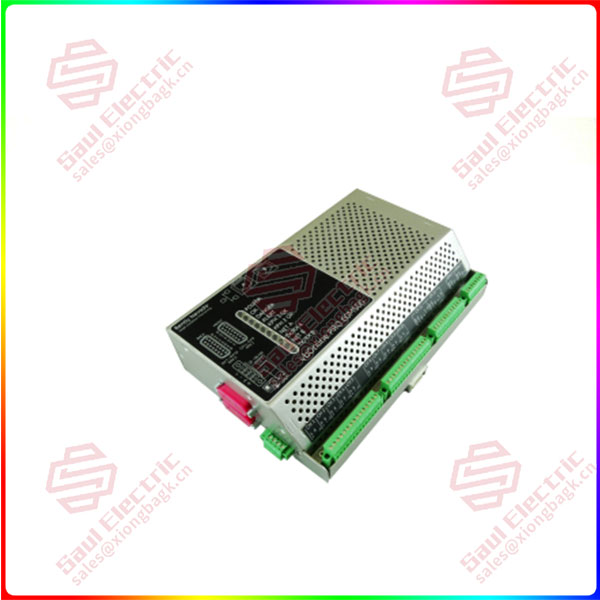

Essential details:60M500 vbOnline Pro Condition Monitoring System

The vbOnline Pro Condition Monitoring System uses sophisticated signal processing algorithms together with machinery operating states to monitor assets continuously.

This system is part of a condition based maintenance program that identifies problems before assets begin to fail.

Benefits of the vbOnline Pro Condition Monitoring System are:

l Cost savings from reduced machinery down time

l Early detection of bearing defects

l Reduction of damage to assets

The monitoring system’s key features are:

l Signal conditioning

l Alarming

l Speed inputs

l Control system communication

The vbOnline Pro Condition Monitoring System communicates with System 1, machine control systems and imports data from external Modbus sensor systems via dual

Ethernet connections. The analog input channels support standard industrial accelerometers using 24 bit analog-todigital conversion over a 40 kHz bandwidth to monitor rolling element bearing machinery and all gearbox configurations.

The vbOnline Pro Condition Monitoring System supports monitoring machinery that works through numerous operating states, power levels, speeds, loads or modes. Data collection can be controlled, compartmentalized and alarmed by any combination of measured parameters, including speed, vibration amplitude, individual measurement alarm status and any parameter from external sources via Modbus.

60M500

lf you need to inquire or purchase ,please send the product models to my email or call medirectly .

sunny He

[Email] sales@xiongbagk.cn

[Mobile] 86-18059884797

[WhatsApp] 86-18059884797

[Skype] sales@saulcontrol.com

60M500 vbOnline Pro Condition Monitoring System

Sophisticated signal processing algorithms extract measurement and health indices from each accelerometer point. The algorithms can be custom tuned to specific bearing and gear box characteristics.

The vbOnline Pro Condition Monitoring System exports trended measurements like direct, bias, speed, gap as well as channel NOT OK status to third party systems such as DCS via Modbus over ethernet.

The vbOnline Pro Condition Monitoring System components are the vbOnline Pro monitor,

System 1, Bently Nevada Monitor Configuration software, transducers, and cables.

Orbit 60 Series is the future of machinery asset protection, condition monitoring and advanced diagnostics. Look beyond just protection.

Orbit 60 Series is Bently Nevada’s next generation of machinery protection and condition monitoring designed to be the most advanced system for all your critical machinery assets, as well as your plantwide assets, across a wide range of industrial applications.

Orbit 60 Series is built on a fully distributable architecture that allows you to monitor all your assets regardless of complexity or location and is intrinsically cyber secure.

When combined with System 1 condition monitoring and diagnostics software, Orbit 60 Series will provide users the ability to create proactive maintenance and fleet management programs for maximum productivity and cost reduction.

1 Year Warranty

1 Year Warranty