By industry, the automotive segment of the industrial segment will hold the highest market share of the collaborative robot market during the forecast period

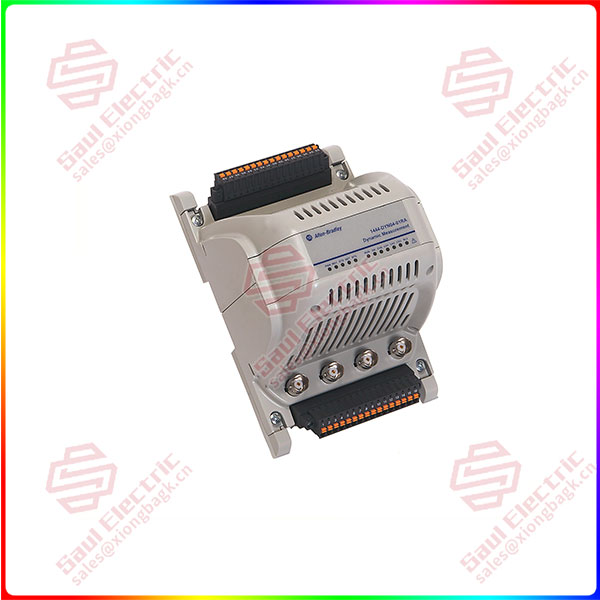

The application of collaborative robots in the automotive industry has revolutionized manufacturing processes, increasing productivity and enhancing worker safety, adaptability and cost-effectiveness. Designed for collaboration with human workers, collaborative robots excel at automating lightweight and repetitive tasks, increasing productivity and maintaining consistent quality. The cobot’s advanced sensors and vision 1444-DYN04-01RA systems ensure a safe working environment by detecting the presence of humans and triggering appropriate responses. The adaptability of collaborative robots allows for easy reprogramming and redeployment, helping to respond quickly to changing production needs. Although the initial investment may be higher, the cost benefits of cobots become apparent through faster return on investment, shortest setup time, and reduced reliance on specialized technicians. In essence, collaborative robots have become an indispensable asset for the automotive industry, shaping the future of manufacturing practices.

By region, Asia Pacific will have the highest CAGR during the forecast period

1444-DYN04-01RA

The Asia Pacific region is one of the major markets of the global collaborative robot market. The region’s focus on cost-effectiveness and the affordability of cobots compared to traditional industrial robots make cobots an attractive option for automation solution participants. Diverse application environments cater to the needs of industries such as electronics, automotive, and food and beverage, facilitating the widespread adoption of collaborative robots. According to the International Federation of Robotics (IFR), robot density in Asia, especially in manufacturing, is 168 robots per 10,000 employees. This indicator shows the popularity and utilization of robots in the manufacturing process in the region. Collaborative robots are designed to work in combination with humans, thereby facilitating a more flexible and interactive approach to automation. It is worth noting that small and medium-sized enterprises (smes) are increasingly embracing cobots, which is further driving the integration of cobots and manufacturing. Government initiatives, including funding, tax incentives, and skills development programs, have actively supported the development and adoption of cobots. While Asia Pacific currently leads the way, the growth potential and concerns about job losses in other regions highlight the dynamic landscape of the evolving collaborative robot market.

1444-DYN04-01RA At the same time, as the aging population in China and Japan causes labor costs to rise, this also leads to the increasing popularity of automation. This has forced companies to adopt automation and collaborative robots to reduce costs. As labor costs increase, China is expected to further increase its investment in automation to maintain its production cost advantage. Therefore, China’s cobot market will remain dominant during the forecast period. Through the “Made in China 2025” policy, China is moving away from simple labor-intensive industries to manufacturing high-tech products such as semiconductors. The presence of some of the most prominent players in the collaborative robot market segment, such as Fanuko Corporation (Japan), Yaskawa Electric Corporation (Japan), Denso Corporation (Japan), Aerobor Robotics Corporation (China), Daming Robotics Corporation (China), Taiman Robotics Corporation (Thailand) and Doosan Robotics Corporation (Korea), is another major factor driving the market in the Asia Pacific region.

1 Year Warranty

1 Year Warranty