“Now the main battlefield of the global robot industry should be in China, and the domestic competitiveness has been reflected in the results of the market, which is actually due to the coordinated development of the domestic Oems and the entire supply chain.” Eft founding team members, chief engineer Xiao Yongqiang recently visited the “Shanghai Hui · Hard branch hard guest” sixth program “New evolution of industrial robots” said.

Xiao Yongqiang said that the localization of core parts is a “card point” encountered in the development process of industrial robots, and now the country has established its own capabilities, and the localization of core parts has achieved a breakthrough.

At the same time, Xiao Yongqiang believes that for industrial robots, there are two measures in the improvement of new quality productivity, one is to improve the optimization and upgrading of the supply chain industrial chain, and the other is to achieve digital transformation.

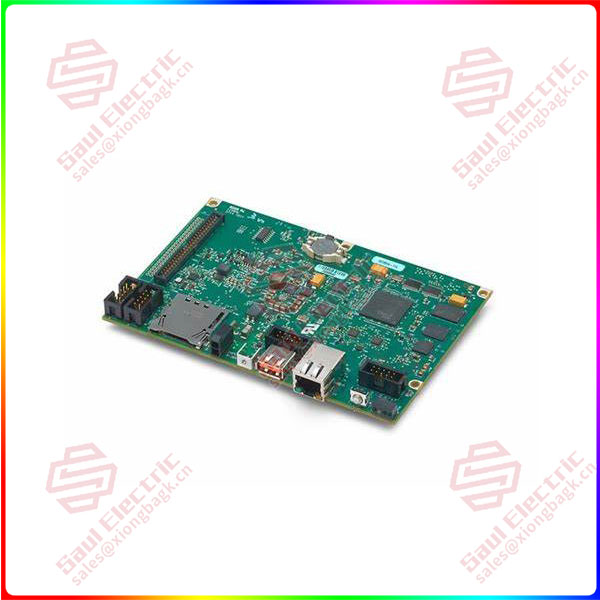

SCRIO-9627 Eft founding team member, chief engineer Xiao Yongqiang

Domestic enterprises focus on resources to catch up with foreign countries

Statistics from the Ministry of Industry and Information Technology show that China has become the world’s largest industrial robot application country for many years. In 2022, China’s industrial robot production reached 443,000 sets, an increase of more than 20%, and the installed capacity accounted for more than 50% of the world’s total.

But for many years the market was dominated by foreign “big four families” (Fanuc, Yaskawa Electric, Kuka and ABB). China Merchants Securities research report shows that in 2022, the “four big families” occupy 40% of the market, and the localization rate is about 30%.

Xiao Yongqiang said: “The development of foreign ‘four big families’ has a history of more than 50 years, so they are very profound whether it is technical products, or the accumulation of processes for specific scenes, which may have some gaps in domestic production.”

However, the industry generally believes that under the “head goose” effect released by domestic robot leaders, Chinese enterprises are catching up and achieving breakthroughs. In recent years, the market share of domestic brands has been climbing, and there have been some new changes in the market pattern.

SCRIO-9627

According to the latest statistics from the High-tech Robot Industry Research Institute (GGII), the share of domestic industrial robots in 2023 exceeded 50% for the first time, reaching 52.45%.

“Many of our customers are in the country, we are closer to the market, close to customers, engineering, engineer dividends to bring us rapid response, rapid industrialization iteration ability is also very strong.” Xiao Yongqiang believes that the advantages of domestic products are obvious.

In addition, Xiao Yongqiang believes that domestic manufacturers, including Efte, have done a very important thing – focus.

“Because we are close to the market, we can focus our resources, especially in some of the domestic development of the industry, we can focus on these points can go very fast, and based on our own technical capability system has been built more perfect, so we are able to quickly break through on these points.” Xiao Yongqiang said.

SCRIO-9627 In the process of focusing and breaking through, Xiao Yongqiang believes that the speed of domestic iteration is very important, “We have a systematic ability to make up where we need to make up, have the ability to quickly make up, which makes our customers more confident in cooperation with domestic enterprises, and domestic enterprises can do better.” Xiao Yongqiang said.

“Domestic competitiveness has been reflected in the results of the market, which is actually due to the coordinated development of domestic Oems and the entire supply chain.” Xiao Yongqiang believes that the current global robot industry’s main battlefield is in China.

“Despite looking at the world, China’s domestic robots are still in their infancy on the overseas stage, and both market share and brand awareness need to be improved.” But we believe the opportunity to catch up is very large based on the capabilities that have been developed at home.” Xiao Yongqiang said.

1 Year Warranty

1 Year Warranty