On April 22, at the 2024 China Industrial Equipment Intelligent Operation and Maintenance Technology Conference, China Machinery Industry Federation and China Mechanical and Electrical Equipment Maintenance and Transformation Technology Association jointly issued the first systematic industry guidance document in the field of domestic industrial equipment intelligent operation and maintenance – “2023 China Industrial Equipment Intelligent Operation and Maintenance Industry Development Blue Book” (hereinafter referred to as: Blue Book).

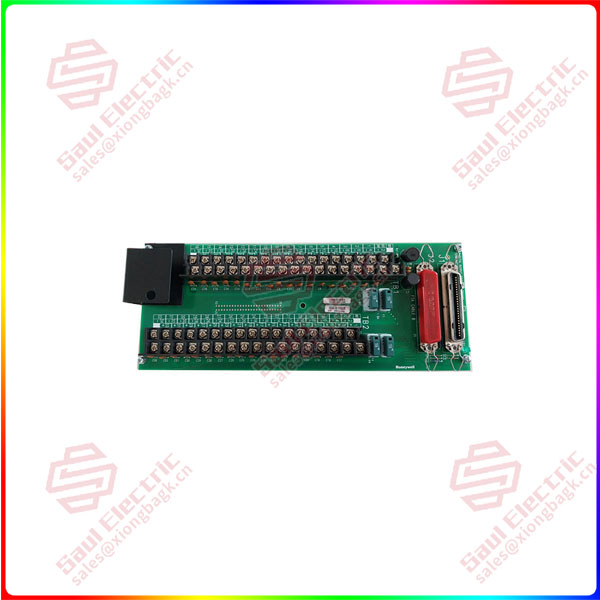

51204156-175 This release has an important guiding significance for the development of intelligent operation and maintenance field, and Hollysys was invited to participate in the preparation of the blue Book and was evaluated as an important contribution to the compilation unit, contributing professional insights to the industrial intelligent upgrading.

The blue book was compiled under the guidance of academicians at home and abroad, and Hollysys, as a member of the editorial board, cooperated with Sinopec, petrochina, CNOOC, China Unicom, Southern Power Grid, National Energy, Three Gorges Group, China Coal Energy, China Shipbuilding, China Aviation, Aluminum of China, China Minmetals, Dongfang Electric, Harbin Electric, Baobu Group, Angang Group, China Sinoma, Shandong Energy, More than 40 leading central enterprises, universities and research institutes, including Tsinghua University, Beijing University of Aeronautics and Astronautics, China University of Petroleum, Beijing University of Chemical Technology and Xi ‘an Jiaotong University, jointly analyzed and shared advanced technologies and practical experience, providing an important reference for the intelligent transformation and development of petrochemical, electric power, metallurgy, mining, machinery, transportation, shipping and other industries.

51204156-175

In the blue book, Hollysys combined with industrial development, technological innovation, application practice and other thinking dimensions, elaborated the challenges encountered in the operation and maintenance of factory equipment, and provided a digital intelligent implementation path for the high-quality development of industry. In recent years, the equipment level of petrochemical enterprises is increasing day by day, and various equipment, systems and facilities are developing in the direction of large-scale, continuous, complicated and intelligent. Due to the huge scale of equipment and facilities assets of petrochemical enterprises and the characteristics of inflammability and explosive, once the equipment is wrong, it is easy to cause the equipment to stop production, and it will cause major accidents such as environmental pollution, fire and explosion, personal injury and death.

51204156-175 In the face of complex and changing equipment failure and security management challenges, Hollysys in the blue book “Intelligent instrument condition Monitoring and Fault diagnosis system (HAMS) and instrument control equipment management platform application” as an example, gives a smart and reliable solution.

Hollysys HAMS Equipment management system is a management system for maintenance, calibration and fault diagnosis of field instruments and regulating valves, and is also an important part of the maintenance and diagnosis system of the whole plant. The system is based on EDDL and FDT/DTM technology to solve the interoperability problem, combined with information and intelligent application requirements, effectively realize the data management and status diagnosis and monitoring of various types of intelligent instruments, improve the ability of proactive and predictive maintenance of equipment, and eliminate the phenomenon of under-maintenance and over-maintenance of equipment. Ensure the stable and reliable operation of the device, so as to improve the availability and profitability of the factory, and improve the digital safety production management level of the enterprise.

With strong research and development capabilities and deep practical experience, Hollyse has helped users successfully solve problems such as extensive management of enterprise intelligent instrument equipment and lack of scientific decision-making in maintenance. At the same time, it is hoped that with the help of the blue Book, the insights will be transformed into the practical force to build China’s intelligent operation and maintenance industry, and create long-term value for the industry.

1 Year Warranty

1 Year Warranty