The process industry plays a vital role in today’s industrial production, especially in key areas such as petroleum, chemicals and metallurgy. These industries not only have a significant impact on the country’s economic development, but also because of the high temperature, high pressure, flammable and explosive risk factors involved in their production process, the safety requirements are extremely strict. In addition, production in the process industry is often continuous, and any unplanned downtime can lead to significant economic losses, so ensuring that security systems are highly available is critical to safeguarding the stable operation of the enterprise.

Process industry safety standards

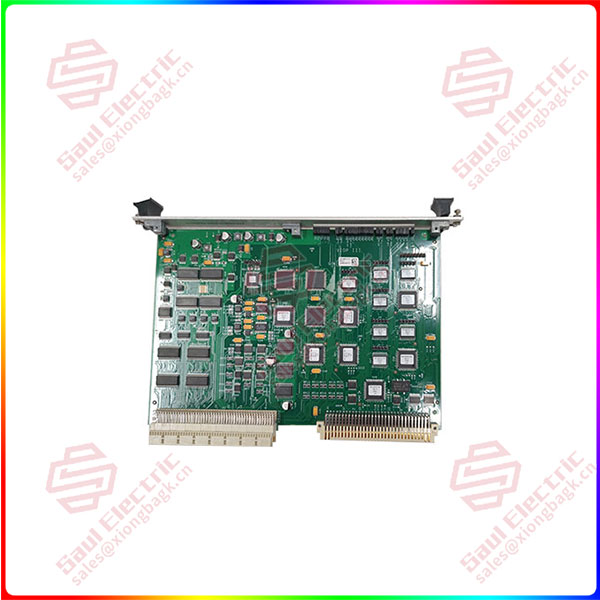

810-046015-010 Safety controls in the process industry are designed, implemented and maintained in accordance with a range of international and national safety standards to ensure the safety of equipment and operations. Some safety standards that can be referred to for process industry safety control are (only some are listed) :

IEC 61508: Functional Safety of Electrical/Electronic/Programmable electronic safety-related Systems is the overall performance standard for safety-related systems, providing guidance for each stage of the safety life cycle

810-046015-010

IEC 61511: Process Safety Instrumentation Systems in the Oil and Gas Industry provides requirements specifically for process safety instrumentation systems in the petroleum, chemical and other process industries

ISA/IEC 62443: Cyber Security of Industrial Automation and Control Systems series of standards dealing with measures to protect industrial control systems from cyber attacks

ISO 13849, Safety of Machinery – Risk assessment and risk Reduction, provides guidance on the design and implementation of safety controls for machinery and electrical equipment.

IEC 62061: Safety of Machinery – Safety-related electrical, electronic and programmable electronic Control Systems is a standard for electrical and electronic control systems used in the safety of machinery.

810-046015-010 The standard covers multiple aspects from risk assessment, security system design and network security to ensure the safety and reliability of the process industry under various operating conditions. When implementing a security control system, enterprises must refer to applicable international/domestic standards based on specific application scenarios.

The company’s product line covers many aspects such as emergency shutdown systems (ESD), isolation grids, burner control, etc., providing a comprehensive security guarantee for the process industry. For example, the PNOZsigma series of safety relays and the PNOZmulti configurable small controllers monitor and respond to emergencies in real time, while the PNOZmulti2 Burner burner management system and the PSS 4000 automation system provide advanced monitoring and control solutions for furnace safety. With these high safety and high availability products and solutions, Pielmagnetics can help users in the process industry achieve safe production, reduce downtime and increase production efficiency.

1 Year Warranty

1 Year Warranty