Industry development trend

Industrial machine industry development trend

1. Accelerated localization of high-end machine tools

The domestic penetration rate in the high-end field is low, and the import dependence is high, but the demand for high-end machine tools continues to be strong. According to the statistics of the Japanese Working Machinery Industry Association, in each month of the fourth quarter of 2022, the order volume from the Chinese mainland was 31.1 billion yen, 29.5 billion yen and 29.7 billion yen, an increase of 28.8%, 11.3% and 1.3% respectively.

Under the requirements of the safety concept of development in the new era, the development of high-end industrial machine tools is crucial, and with the significant improvement of the independent development capability and industrial technology level of China’s industrial machine tools, some domestic enterprises have gradually focused on the localized development of high-end machine tools.

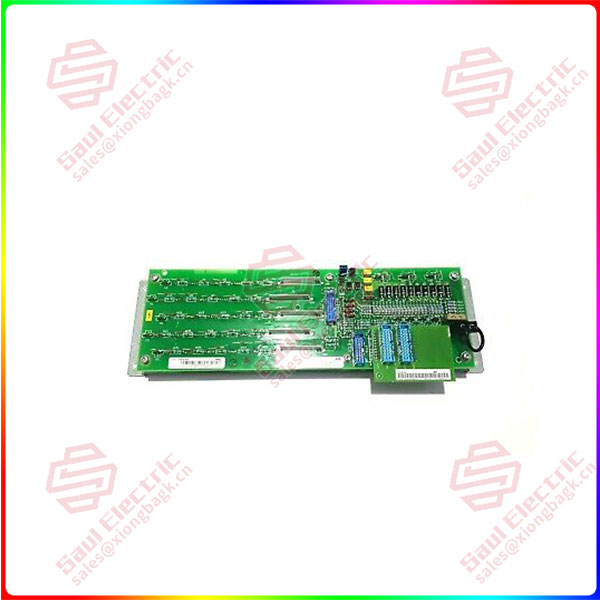

SDCS-PIN-51 According to China Customs data, the total import and export of machine tools in 2022 was 33.36 billion US dollars, an increase of 0.9%, of which imports were 12.4 billion US dollars, down 10.2%; Exports were $20.95 billion, up 9 percent year on year. Affected by the conflict between Russia and Ukraine, Russia accounts for the highest proportion of China’s total exports. Most Oems export to Russia, Iran and other countries and regions through agents, but at present, they can only sell three-axis and four-axis machine tools and their supporting systems, and can provide OEM production and labeling.

SDCS-PIN-51

2. The state will increase policy support for the industrial mother-machine industry

The state will continue to increase the key and breakthrough links in the industrial mother-machine industry chain. CNC system because of its hardware and software integration, high technical barriers, localized development is necessary, the potential “jam neck” risk will seriously affect the security of national defense construction. Lead screw, guide rail, bearings and other key parts due to the difficult manufacturing process, product stability and reliability verification cycle is long, a single enterprise is difficult to achieve a comprehensive breakthrough in a short time, the need for greater external support joint research.

3. Digital and intelligent upgrade of industrial mother-machine

SDCS-PIN-51 Large-scale, intelligent and complex is the future development trend of industrial mother-machine, and it is also an important direction for advanced enterprises to carry out technological innovation and differentiated competition. With the development of a new generation of information technology, industrial mother-machines will achieve remote monitoring, accurate control, predictive diagnosis, intelligent maintenance and other functions, greatly improving the automation level and operation efficiency of the system.

4. Industrial mother-machine is more efficient and environmentally friendly

Industrial machines will pursue higher energy efficiency and lower environmental impact, implement efficient and energy-saving transformation of motors, and develop cleaner production technologies. This is conducive to the green development of enterprises and the sustainable development of society.

1 Year Warranty

1 Year Warranty