Third, to achieve lean enterprise supply chain management

Lean supply chain is to accurately identify all kinds of redundancy in the supply chain network, implement the process reshaping from product design to customer use, and cooperate upstream and downstream to eliminate unnecessary costs and waste, shorten business processes and cycles, and meet customer needs with maximum and highest efficiency with as few resources as possible.

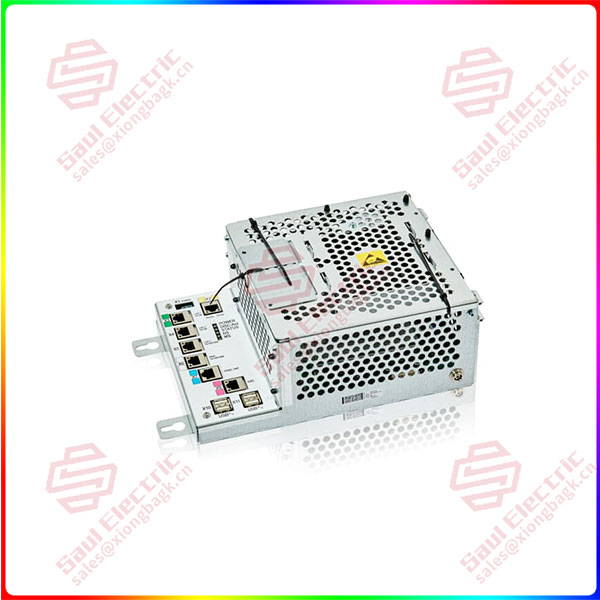

5. DSQC1018 Eliminate waste in all aspects of the supply chain. Enterprises can flexibly use total cost accounting, value stream analysis and other methods to accurately identify excessive production waste, redundant processes (material handling distance, redundancy of production actions, repetitive labor, etc.) waste, defect or error waste, inventory waste and other contents in the whole process of supply chain, timely analyze and find out the causes, and adopt necessary monitoring and early warning means. Implement improvement methods such as improving turnaround speed and reducing process variance to eliminate waste and achieve optimal allocation of resources.

(6) Promote the optimization of the whole chain process of the supply chain. Enterprises should strengthen the information connection with key suppliers and major users, and strive to eliminate the information asymmetry in demand forecasting, design and scheduling, transportation routes and competitive strategies, so as to improve the delivery capacity of the supply chain. Use visual monitoring portrait means to carry out differentiated demand forecasting for different material categories, and streamline the forecast categories and material categories of grass-roots units. Improve the logistics processes such as circular pickup and pickup and delivery combination, so that raw materials, semi-finished products and finished products continue to be in a state of turnover, and reduce the proportion of warehouse storage forms.

DSQC1018

7. DSQC1018 Improve the standardized supply chain system. Encourage enterprises to actively improve supply chain technology, equipment and other standards, and work with suppliers, carriers, and sellers to improve equipment compatibility and standardization. Strengthen product standardization construction, and reasonably control the types of spare parts and the number of suppliers. Encourage enterprises and upstream and downstream enterprises in the supply chain to achieve unified material coding, jointly develop or participate in general standards, key technical standards and industry application standards, etc., to promote the effective connection of upstream and downstream standards in the supply chain.

1 Year Warranty

1 Year Warranty