Machine vision is a branch of artificial intelligence that automatically receives and processes an image of a real object through optical devices and non-contact sensors to obtain desired information or to control the movement of a machine. Simply put, machine vision is the use of machines instead of human eyes to make measurements and judgments. The application field of machine vision technology is very wide, covering industry, agriculture, medical, military, aerospace, meteorology, astronomy, public security, transportation, security, scientific research and other industries of the national economy.

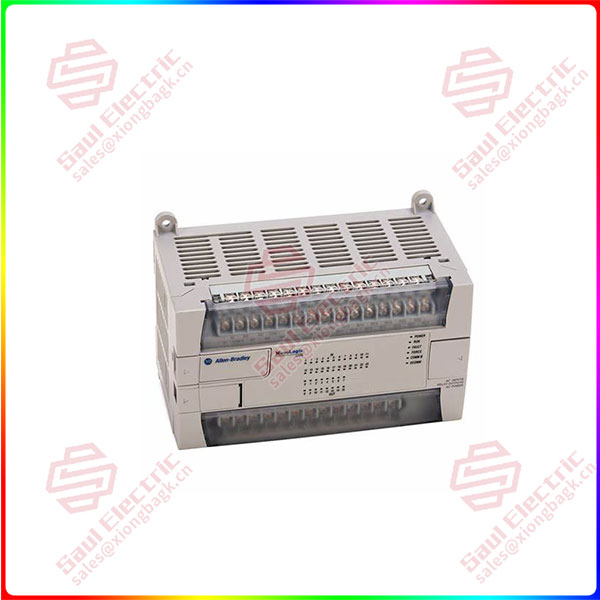

1762-L40BWA With the continuous progress of technology and the continuous expansion of application fields, the scale of China’s machine vision market has shown continuous growth. According to the “2024-2029 China Machine vision Industry Market Prospect Forecast and Future Development Trend Research Report” released by the China Business Industry Research Institute, the size of China’s machine vision market reached 18.512 billion yuan in 2023, an increase of 8.49%. China Business Industry Research Institute analysts predict that the size of China’s machine vision market will grow to 20.717 billion yuan in 2024.

Data source: GGII, China Business Industry Research Institute

Machine vision industry development prospects

1. Policy support for industry development

Machine vision is a hardware and software integration system, which applies the concept of “machine instead of human eyes” to industrial manufacturing, and is one of the core elements of the fourth Industrial revolution (Industry 4.0). Its hardware equipment mainly includes light source, lens, camera, etc., and its software mainly includes traditional digital image processing algorithms and image processing algorithms based on deep learning. As a key technology field combining manufacturing and artificial intelligence, in recent years, the National Development and Reform Commission and the Ministry of Science and Technology have successively issued guidance and support policies such as “Opinions on Accelerating the high-quality Development of Manufacturing Services” and “Guiding Opinions on Accelerating Scene Innovation to Promote high-quality Economic Development with high-level application of artificial Intelligence”. It provides a good policy environment for the machine vision industry. Compared with human eye observation, machine vision has the advantages of strong accuracy, fast speed, strong adaptability, high objectivity, strong repeatability, stable and reliable detection effect, high efficiency, convenient information integration, etc., and is the future development direction of digital, networked and intelligent industrial manufacturing.

1762-L40BWA

2. The downstream application field of machine vision continues to expand

With the improvement of industrial automation and intelligence, machine vision is gradually used in production and manufacturing. At present, the application of machine vision equipment has penetrated into many major industries of the national economy, including electronic information manufacturing, semiconductors, automobiles, pharmaceuticals, food and packaging machinery, printing machinery and other fields. In the downstream application field, the 3C electronics industry is the most widely used field of machine vision, accounting for 25%; Followed by automotive, semiconductor, lithium battery and other industries. With the expansion of global wafer production capacity, machine vision technology is being applied to more high-value application scenarios, and the demand for machine vision applications in wafer inspection, cutting, and packaging is also increasing.

3. Machine vision localization process is accelerating

1762-L40BWA In recent years, domestic machine vision enterprises have been significantly improved in terms of independent research and development capabilities. In the past, domestic enterprises mainly relied on imported equipment and technology, and now, more and more domestic enterprises are beginning to have independent research and development capabilities, able to produce competitive machine vision products. These products have certain advantages in performance, price, service and so on, and have gradually gained market recognition. At the same time, the integration ability of domestic machine vision enterprises in the upstream and downstream of the industrial chain is also increasing. With the continuous breakthrough and innovation of technology, domestic enterprises have begun to transform from simple equipment agents to system integration and solution providers. These companies can not only provide machine vision hardware equipment, but also provide customized software, algorithms and system integration services according to customer needs, providing customers with a full range of machine vision solutions.

1 Year Warranty

1 Year Warranty