Description

Overview

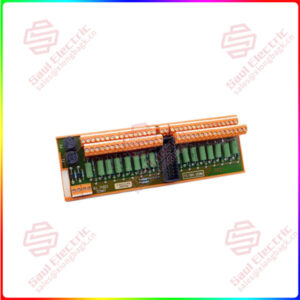

Essential details:UAD155A0111 3BHE029110R0111 Logic pulse controller

Product Description

UAD155A0111 product details are as follows:

Basic information

Make and Model: ABB UAD155A0111

Applications: Mainly used in industrial automation and robotics, such as tank farm, batching/mixing, filling/dispensing, weight inspection, weight level and force measurement applications.

Technical characteristics

High precision control:

Using high-precision digital signal processing technology, it can achieve high-precision logic pulse control to ensure the precise movement of robots and automation equipment.

High speed response:

With fast response ability, it can process various input signals in real time, and quickly output control pulse, improve the dynamic response performance of the system.

Programmability:

Support programmable control, users can program a variety of logic pulse control algorithms to meet the needs of different application scenarios.

Communication capability

Allen-Bradley Remote I/O (RIO) network communication is now supported, such as 1756-DNB, 1756-RM, etc.

Extend FBI100 to 100 series FBM fieldbus, such as HDLC, etc.

UAD155A0111 3BHE029110R0111

Product parameter

Power requirements:

Input voltage: 12 ~ 48 VDC

Maximum input current: 0.6A

Current overload protection: built-in, maximum withstand current 3A

Reverse polarity protection: built-in

Buffer time: minimum 13ms at 24VDC

Organization Specifications:

Case: IP40 reinforced aluminum alloy

Size: 145.3mm (H) × 75mm (W) × 108.7mm (D)

Weight: 490g

Installation method: industrial rail type and wall mounted type

Environmental parameter

Operating temperature: -40℃ ~ 75℃ (40℉ ~ 167℉)

Storage temperature: -40℃ ~ 85℃ (-40℉ ~ 185℉)

Working humidity: 5% ~ 95% (no condensation)

Certification and testing

Safety Specifications: UL 508, EN 60950-1, IEC 61131-2

Electromagnetic Interference (EMI) : FCC 47 CFR Part 15 Subpart B Class A, IEC 61000-6-4, EN 55022

Electromagnetic Tolerance (EMS) : IEC 61000-6-2

Industrial environmental project testing: including low temperature, high temperature, humidity, shock, free drop, vibration and high potential testing.

Input voltage: 12 ~ 48 VDC

Maximum input current: 0.6A

Current overload protection: built-in, maximum withstand current 3A

Reverse polarity protection: built-in

Buffer time: minimum 13ms at 24VDC

Organization Specifications:

Case: IP40 reinforced aluminum alloy

Size: 145.3mm (H) × 75mm (W) × 108.7mm (D)

Weight: 490g

Installation method: industrial rail type and wall mounted type

Environmental parameter

Operating temperature: -40℃ ~ 75℃ (40℉ ~ 167℉)

Storage temperature: -40℃ ~ 85℃ (-40℉ ~ 185℉)

Working humidity: 5% ~ 95% (no condensation)

Certification and testing

Safety Specifications: UL 508, EN 60950-1, IEC 61131-2

Electromagnetic Interference (EMI) : FCC 47 CFR Part 15 Subpart B Class A, IEC 61000-6-4, EN 55022

Electromagnetic Tolerance (EMS) : IEC 61000-6-2

Industrial environmental project testing: including low temperature, high temperature, humidity, shock, free drop, vibration and high potential testing.

APPLICATION

The application field of UAD155A0111 is mainly concentrated in industrial automation and robotics, the following are some specific application scenarios:

Tank farm automation:

In the petrochemical, food, pharmaceutical and other industries in the tank farm, UAD155A0111 can be used to control the operation of various valves, pumps and agitators and other equipment, to achieve automated operation in the tank farm, improve production efficiency and safety.

Dosing/Mixing System:

On the production line, batching and mixing are common processes. UAD155A0111 can control the amount and mixing time of various raw materials according to the preset formula to ensure the consistency and stability of product quality.

Filling/Dispensing System:

In the beverage, cosmetics, food and other industries, filling and distribution is an important part of the production process. The UAD155A0111 can precisely control the filling speed and dispensing volume, improving production efficiency while reducing waste.

Weight checking system:

In the packaging industry, inspection is an important step to ensure product quality. The UAD155A0111 can be used with a load cell to monitor product weight in real time and adjust production parameters as needed.

Weight level and force measurement applications:

In some applications requiring accurate weight or force measurement, such as weighing equipment, material handling, etc., the UAD155A0111 can provide accurate signal processing and control functions to ensure the accuracy of the measurement.

Robot control:

With the rapid development of robot technology, UAD155A0111 is more and more widely used in the field of robot control. It can be used to control the trajectory, speed and attitude of the robot to achieve complex automatic operation.

Production line monitoring and data acquisition:

UAD155A0111 can be used with various sensors and actuators to collect the operating data of the production line in real time and transmit it to the monitoring center through the network to realize the remote monitoring and management of the production line.

System integration and transformation:

For existing industrial automation systems, UAD155A0111 can be used as an independent control unit to connect and communicate with other equipment through standard interfaces to achieve system integration and transformation.

In short, UAD155A0111 has a wide range of application prospects in the field of industrial automation and robotics due to its high performance, high reliability and easy integration.

Shipping

Superiority products UAD155A0111 3BHE029110R0111 Logic pulse controller

| 2MLR-CPUHT HONEYWELL CPU HT bus function | 3500/15 127610-01 Bently Nevada Digital input module |

| 177313-01-01 BENTLY NEVATA Vibration monitoring module | 3500/50 133388-02 BENTLY NEVADA Tachometer monitoring module 4 channels |

| PXIE-6556 NI Automatic industrial control module | 3500/40-03-00 176449-01 BENTLY NEVADA Expansion axial position module |

| PFCL201CE ABB Pressure sensor controller | 3500/15 Plastic panel BENTLY NEVADA Ac and DC power supplies |

| MTL BPHM64 Eaton Safety grid base plate | X20CP1586 B&R The core product of B&R’s I/O system line |

| 1794-IF4IXT Allen Bradley Flex I/O 1794 series input module | IC698PSA350 GE High capacity power module |

| 1734-IM4 Allen Bradley POINT I/O 4 Point Digital Input Module | VMIVME 3215-000 GE Computer module |

| 1769-ECR Allen-Bradley Right end cover (ECR) module used together | 201TI GE Microprocessor-based electrical transmitter |

| 136188-02 Bently Nevada Ethernet /RS232 Modbus I/O module | 3500/05-01-02-00-00-01 BENTLY System rack |

| AI02J ABB Analog input module | PM865K02 ABB controller |

| DSSA165 ABB Ac power module | 3500/22-01-01-00 138607-01 BENTLY Transient data interface before and after the size card module |

| PXIe-1073 NI PXI Chassis | IS420UCSBH4A GE Controller module manufactured by General Electric |

| F860-CA HONEYWELL Series C “fieldbus interface module | D201376 METSO Analog input module |

| DSSA165 ABB Ac power module | D201376 METSO Analog input module |

| 125840-02 Bently Power module | IS420UCSBH4A GE Controller module manufactured |

| 125680-01 BENTLY Displacement detection module | IS220PRTDH1A 336A4940CSP6 GE Controller module |

1 Year Warranty

1 Year Warranty