Description

Overview

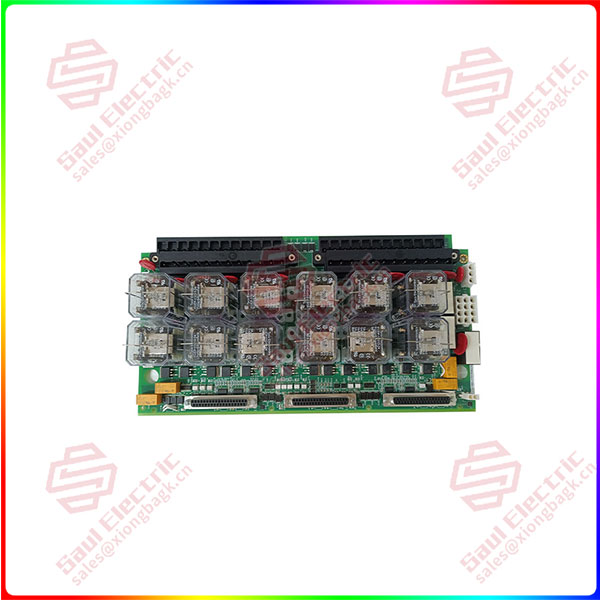

Essential details:IS200TREGH1BDB trip emergency termination board

Product Description

The GE IS200TREGH1BDB is a trip emergency termination board manufactured by General Electric (GE) for use in gas turbine control systems or safety systems. Here are some key details about the product:

Product model: IS200TREGH1BDB.

Function: The module is mainly used in the gas turbine control system or safety system, and plays a trip and emergency shutdown function.

Application scenario: In gas turbine systems, trip and emergency termination functions are typically used to automatically or manually shut down or stop the gas turbine when conditions are detected that compromise the safety or performance of the system. These conditions may include overheating, excessive speed, excessive vibration, fuel supply problems, or any other condition that could damage the gas turbine or surrounding equipment.

Emergency termination board Features:

Contains logic circuits or software that implement tripping conditions.

Provide one or more manually operated emergency termination buttons.

Provide information on gas turbine status, trip conditions, and emergency termination operations through indicators or other display devices.

Redundant designs may be used, including redundant power supplies, controllers, and communication interfaces.

May interface with other control systems of the gas turbine (e.g. DCS, SIS) to share information and perform coordinated trip and emergency termination operations.

Advantages of modular design:

Flexibility: The modular design allows users to select different modules according to their needs to meet specific application requirements.

Maintainability: If a module fails, it can be easily replaced without affecting the rest of the entire trip emergency termination board.

Standardization: The modular design promotes standardization so that different modules can share the same interface and specifications.

Scalability: As technology continues to evolve, the modular design allows users to easily add new modules to the trip emergency termination board to support new features or improve performance.

Easy integration: The modular design makes the trip emergency termination board easier to integrate with other systems or devices.

Physical characteristics: The components on the IS200TREGH1BDB trip emergency termination board consist of a series of square transformers that are covered by clear plastic and silver wires and contain information about the components, such as part number and voltage. In addition, there are two large black terminals that occupy the space on the left edge of the board, a total of 48 terminals, evenly divided between the two terminals.

These features make the GE IS200TREGH1BDB an indispensable safety component in gas turbine control systems, ensuring that the turbine can be shut down quickly and reliably in the event of an emergency, protecting equipment and personnel.

IS200TREGH1BEC

Product parameter

Model: IS200TREGH1BDB.

Input voltage: 24V DC.

Output voltage: 0 ~ 10V DC.

Operating temperature range: -40°C to 85°C.

Dimensions: 100mm × 50mm × 30mm.

Tripping logic: Contains a logic circuit or software that implements tripping conditions and triggers tripping actions when these conditions are met.

Emergency stop button: One or more manually operated emergency stop buttons are provided so that the operator can quickly shut down the gas turbine in an emergency.

Status indication: Provides information about gas turbine status, trip conditions, and emergency termination operations through indicator lights or other display devices.

Redundant design: To improve reliability, the emergency termination board may be redundant in design, including redundant power supplies, controllers, and communication interfaces.

Communication interface: Support a variety of communication interfaces, such as Ethernet, RS-232, RS-485 and so on.

Response time: Depends on the application, but is usually faster.

Compatibility: Compatible with other industrial automation equipment and control systems.

APPLICATION

Oil and gas industry: Used to monitor and control equipment during oil drilling, transportation and processing to ensure that equipment can be quickly shut down or stopped if potentially hazardous conditions are detected.

Chemical manufacturing: Used in the chemical production process to monitor and control the operating status of chemical reactors, pumps, agitators and other equipment to prevent overheating, speeding or other conditions that may lead to accidents.

Power production: In the field of power production, such as power plants, it is used to monitor and control key equipment such as turbines and generators to ensure timely tripping in case of failure or abnormal conditions to ensure the safety of personnel and equipment.

Steel plant: Used in the steel production process to monitor and control the operation of equipment such as blast furnaces and rolling mills to prevent overheating, overload or other conditions that may cause damage to equipment.

Cement plant: In the cement production process, it is used to monitor and control the operation of kiln, mill and other equipment to ensure that in the event of abnormal conditions, it can trip in time to avoid accidents.

Ship: In the ship’s power and propulsion system, it is used to monitor and control engines, generators and other equipment to ensure that the power can be quickly cut off in case of failure or emergency to ensure the safety of the ship.

Paper industry: Used in the paper production process to monitor and control pulp and paper production equipment to prevent overheating, overload or other conditions that may cause damage to equipment.

Industrial automation and control systems: In various industrial automation and control systems, it is used to achieve real-time monitoring and control of the production process to ensure that it can respond in time when abnormal conditions occur.

Superiority products IS200TREGH1BDB trip emergency termination board

| UFC762AE101 3BHE006412R0101 Main board module | IC697CMM742-DC Series 90-70 Communications Module |

| 87199-01 Stator insulation monitor | FC-TSRO-0824 Digital Output Field Termination Assembly |

| MVME55006E-0161R VMEbus Single-Board Computer | MVC3001-4003A ALSPA MV3000 Delta Controller |

| 3500/25 149369-01 Keyphasor module | 6SM57M-3.000 Synchronous Servomotors |

| 3500/92 136180-01 Keyphasor module | 05701-A-0282 Modbus Interface Module Kit RS422/485 |

| 1X00416H01 POWER SUPPLY 24V 300W & 25V 500W OUT DIN-RAIL MOUNT | 3500/91 190782-01 EGD gateway module |

| 5X00241G02 Ovation Westinghouse Controller module | 05701-A-0361 System 57 MODBUS Interface |

| 489-P5-LO-A20 generator management relay | 3500/65 145988-02 16-Channel Temperature Monitor |

| TRICON 3805E TRICONEX Analog Output Modules | 3500/65 172103-01 16-Channel Temperature Monitor |

| 5X00226G02 Ovation Westinghouse Controller module | 136188-02 Ethernet/RS485 Modbus I/O Module |

| MC-4/11/10/400 PowerDrive Motion Controller | PCI-6733 Analog Output Device |

| 2MLR-CPUH/T MasterLogic Programmable Logic Controller | 3ASC25H209 DATX110 I/O board control module |

| KJ4002X1-BA1 Left 8 Wide Vertical Carrier | CE4002S1T2B5 Standard I/O Termination Block |

| S72402-NANANA S700 digital servo drive | CE4005S2B4 Standard I/O Termination Block |

| SCYC55830 58063282A Trigger plate | PCI-4462 Sound and Vibration Device |

| IC697CMM742-DC Ethernet Interface Communications Modules | TU890 3BSC690075R1 compact MTU for the S800 I/O |

| PPC322BE1 HIEE300900R1 Industrial drive function module | KJ4001X1-BE1 12P0818X072 REV:L 8 Wide I/O Carrier with Shield Bar |

| VMIVME-3122 High-Performance 16-Bit Analog-to-Digital Converter (ADC) | KJ2201X1-JA1 Redundant SLS Terminal Block |

1 Year Warranty

1 Year Warranty