“If industrial automation is compared to people, the control layer is the human brain, the driving layer is the nervous system that sends instructions, and the executive layer is the hands and feet…” In the Huichuan Industrial Control Museum, a topological map bringing together dozens of industrial automation products is particularly eye-catching, and Huichuan technology breaks down industrial control into five levels: execution/sensing layer, drive layer, control layer, edge layer and information layer. In order to organically integrate these five levels, it is necessary to establish a solution platform that integrates industrial automation and digitalization. At present, there are no more than five companies in the world with such capabilities, and Huichuan Technology is one of them.

Li Ruilin, vice president of Huichuan Technology, told the Securities Times that the company will release its self-developed fully integrated, full-scene factory automation software platform IFA at the China Industry Fair in September. The IFA software platform deeply integrates all categories of products of the execution/sensing layer, drive layer, control layer and edge layer in industrial automation, and can be fully linked with the upper-layer information layer to realize the integration of automation, digitalization and intelligence, and provides self-selected generation solutions from basic automation to leading intelligence for different industrial scenarios. The successful launch of the IFA software platform will completely break the monopoly of Western industrial automation giants in this field and fill the long-term gap in domestic related technologies.

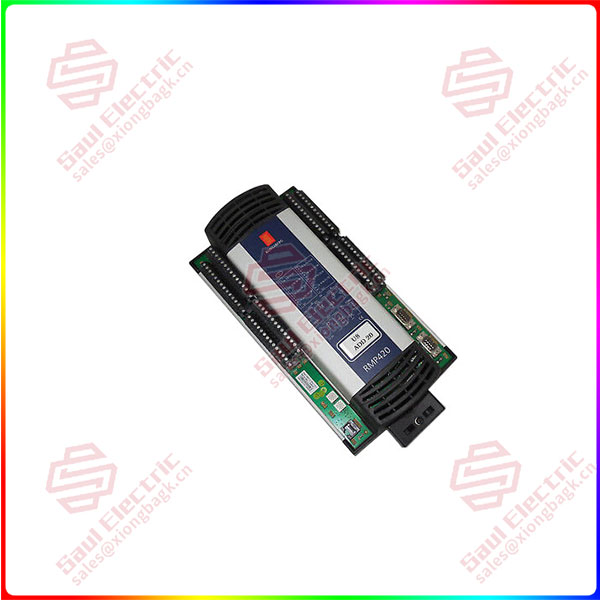

RMP420 Autonomy:

Industrial hardware and software are completely controllable

In the Huichuan Industrial Control Museum, the historical picture of industrial civilization unfolds slowly – from cutting stone to making fire to digital factories, manufacturing industry has experienced the age of steam, the age of electricity, the age of automation and the age of digital, and is now transforming to the age of intelligence. However, the development of more than two hundred years to make the industrial scene all-inclusive, the relationship between the equipment is complicated, how to make the production more efficient and intelligent, is the subject that industrial control enterprises must solve. From the beginning of its establishment, Huichuan Technology has taken it as its mission and continued to tackle problems in this field.

“Huichuan technology has experienced more than 20 years of development, starting from the inverter and elevator integrated controller, and then entering precision machining by servo products, and then cutting into the control layer of automation through PLC, robot, etc.” After the listing of the company in 2010, the company continued to expand its product line, enter the photovoltaic inverter, automotive air conditioning, new energy vehicle electric control and other industries, provide automation products that fit the application, and continue to improve the types of versatile products such as vision, motor, sensor, pneumatic, until it covers all categories of automation. It has trained the ability of automation products and comprehensive solutions for the whole field of optically mechanical hydraulic and gas control.” Li Ruilin introduced that based on a solid technical foundation and broad development vision, in 2019, Huichuan Technology has entered a new era – the ecological era, and the company has comprehensively laid out industrial software.

RMP420

At the beginning of Huichuan Technology business in 2003, facing the domestic industrial control market which was almost monopolized by foreign brands, the company achieved a successful breakthrough. In recent years, the industrial control market has gradually entered a new era of software intelligence, and Huichuan technology has once again achieved a breakthrough and obtained a place in the fierce international competition, which is behind the further spontaneity of the company after the development and growth, but also the consciousness of helping new industrialization, accelerating domestic substitution and industrial upgrading.

“All industrial automation companies, if they want to gain a foothold in the international market, must completely realize the complete autonomy and control of industrial hardware and software to ensure that there are no shortcomings in the solution.” Li Ruilin further said that as a large-scale integrated industrial software platform product, the successful research and development of IFA has allowed the company to have the confidence of international industrial giants to “arm wrestle”.

RMP420 According to Wang Xinxing, a technical engineer of Huichuan and the first generation of IFA R & D personnel, at the beginning of the establishment of IFA team, the company did not have very rich experience in large-scale industrial software development, and there was a lack of enough professional developers in China; At the same time, key technologies such as compilers, real-time operating systems, virtualization, and core algorithms are precisely the fields that are “stuck”, and it is difficult for the team to obtain corresponding technologies and high-level talents. However, Huichuan Technology has faced the difficulties, and has established R & D centers in Xi ‘an and Germany, fully integrating domestic industrial software talents and international experts, combining software engineering strength and process support, to accelerate self-hematopoietic and talent training.

“In less than five years, we completed the development of this large-scale industrial software, and achieved core technology breakthroughs such as fully autonomous ides, compilers, real-time operating systems, virtual control and simulation, forging an elite R&D team of hundreds of people.” Of course, to achieve these results, we invest more than 100 million yuan in research and development every year.” Wang Xinxing said.

1 Year Warranty

1 Year Warranty