On August 15, 2024, Bently Nevada, Inc., a leading global provider of machinery monitoring and protection solutions, announced the launch of its new speed monitoring module 3500/50M. Designed for industrial automation and process control systems, this module provides accurate speed monitoring to ensure equipment is operating optimally.

The 3500/50M speed monitoring module is a dual-channel module that accepts signals from proximity probes or magnetic pickups to determine shaft rotation speed, rotor acceleration or rotor direction. The module compares these measurements with a user-programmable alarm set point and issues an alarm when the set point is exceeded, enabling real-time monitoring and early warning of device status.

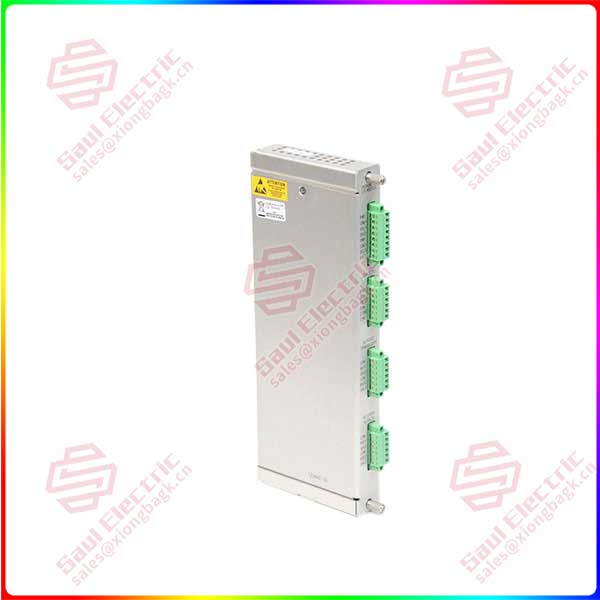

3500/50M

The module adopts advanced signal processing technology, which has the characteristics of high precision and fast response. Its wide measurement range, ranging from 1 Hz to 10 kHz, can meet the needs of different industrial applications. At the same time, the 3500/50M module has good temperature adaptability and can work stably in the environment of -40°C to 125°C, which is suitable for a variety of industrial scenarios, such as power, petrochemical, manufacturing and so on.

With the introduction of the 3500/50M speed monitoring module, Bently Nevada’s product line is further enriched, providing customers with more options and solutions. According to the company, the launch of this module will help improve the reliability and efficiency of industrial automation systems, reduce maintenance costs, and improve production safety.

1 Year Warranty

1 Year Warranty