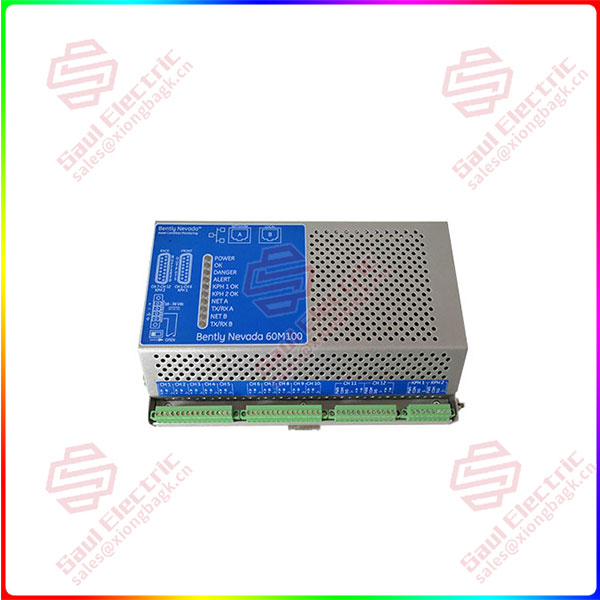

The Bently Nevada 60M100-00 monitor module is an advanced solution designed for vibration monitoring and mechanical fault diagnosis of industrial equipment. It combines high-precision vibration measurement, signal processing and fault diagnosis functions, and is widely used in the maintenance and management of wind turbines, turbines and other critical industrial equipment, providing important technical support for these industries.

The monitor module offers a variety of features and benefits, including but not limited to:

High-precision vibration monitoring capability, which can monitor the vibration speed, acceleration and displacement of the equipment in real time.

The real-time fault diagnosis function identifies and diagnoses mechanical faults such as bearing wear, unbalance and loosening by collecting and analyzing vibration data.

Powerful signal processing capabilities, using advanced algorithms for filtering, noise reduction and feature extraction, improve signal quality and accuracy of fault diagnosis.

Flexible configuration and integration options support a variety of communication protocols and interfaces for easy data exchange and integration with other systems.

60M100-00

The physical characteristics of the 60M100-00 monitor module include operating temperatures ranging from -40°C to +85°C and relative humidity up to 95%. In addition, the vibration measurement range of the module is 0.001 g RMS to 10 g RMS, and the bearing condition monitoring function, including bearing vibration spectrum analysis, temperature monitoring and lubrication monitoring.

The Bently Nevada 60M100-00 monitor module, with its high accuracy, high reliability and ease of use, effectively improves the reliability and safety of industrial equipment, while reducing maintenance costs. It is suitable for a variety of industrial applications, including power generation, oil and gas, chemicals and water treatment, helping companies to achieve real-time monitoring and management of equipment status

1 Year Warranty

1 Year Warranty