Emerson’s implementation of MTP helps reduce risk, speed product to market, realize projected returns on capital projects and reduce costs. High resolution image

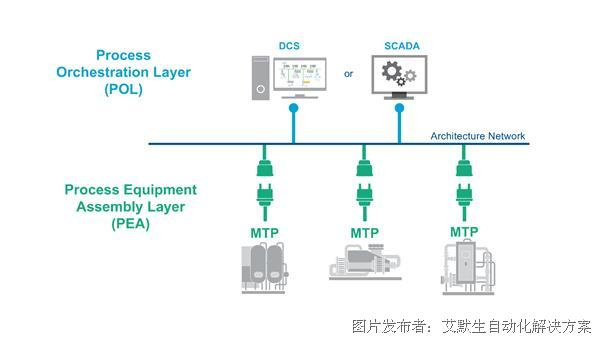

Emerson MTP tools reduce local engineering time and risk through nearly plug and play integration. PACSystems PLCs and DeltaV Automation systems both support integration with third-party components or marshalling layer systems that use the MTP standard. High resolution image

Simple and practical MTP integration enables modular manufacturing, reduced capital and operational costs, and accelerated automated deployment

AUSTIN, Texas (June 3, 2021) — Today Emerson announced the integration of the new MTP process automation standard into its control systems as part of an ongoing effort to help manufacturers speed to market and reduce project and operational costs. Emerson is one of the first automation vendors to support the International Process Industry Automation Users Association (NAMUR) Modular Type Packaging (MTP) standard for Distributed control systems (DCS) and Programmable Logic Controllers (PLCs).

The key challenge for process industries, particularly the life sciences and chemical industries, is the time it takes to bring a product to market or change operations to accommodate a new product. Due to many process changes, it may take weeks or longer for engineers to integrate manufacturing skid mounted equipment and corresponding automation systems. NAMUR has been working with industry leaders such as Emerson to develop the MTP standard to establish a common, open standard that enables shorter engineering development times and near-plug and play integration with new equipment. Emerson estimates that using its MTP tools can save manufacturers and system integrators weeks of project time and hundreds of thousands of dollars in engineering costs compared to traditional integration tools that do not adopt the MTP standard.

“MTP is an important step in helping manufacturing respond more quickly to a changing market,” said Sean Sims, vice president of marketing for Emerson DeltaV DCS Platform. Emerson continues to support and innovate industry standards through the implementation of the MTP tool. The integration between DeltaV and PACSystems automation systems, as well as with third-party automation systems, helps enable more modular, flexible manufacturing, which in turn helps customers speed to market.”

By incorporating the MTP standard into DeltaV™ and PACSystems™ automation systems, Emerson eliminates the need for additional engineering tools or special integration tools for the end user or system integrator. The Emerson MTP tool creates a profile for PACSystems PLC and AMS mechanical prediction equipment that is automatically integrated into DeltaV DCS. PACSystems and DeltaV systems both support integration with third-party components or marshalling layer systems that use the MTP standard.

By adopting the MTP standard, companies can reduce project time and reduce operational risk, easily accelerating key products to market. For the pharmaceutical and biotechnology industries, MTPS help enable flexible manufacturing of “international standard style”, with minimal redesign to enable interchangeability of skid mounted equipment. More flexible manufacturing means that the equipment can be switched on site more quickly, just as doctors can quickly tailor treatments to different patients’ needs.

As part of the first release of the MTP, Emerson also took an important step to import reliability data from manufacturing equipment into the DeltaV system. Operators can assess how the health of plant assets will affect operations and production by using asset health data from the AMS Asset Monitoring Edge analysis facility.

1 Year Warranty

1 Year Warranty