In the just concluded “2023 Metalworking Industry – Jung Technology Innovation Award” selection activity, with the Chinese team independently developed and manufactured KR CYBERTECH nano ARC HW Edition (click for details) arc welding robot, Kuka China successfully won the “Automation and Industry 4.0” category award.

Fu Yongxiang, Product Manager of Kuka China, said that we are very honored that this product has been favored by Jung Industrial Media and professional judges. The metal processing industry has developed very rapidly in recent years, especially industrial robot welding, and the market penetration rate has increased rapidly year by year. Now, Kuka not only has this excellent arc welding robot, but also has a complete arc welding process package, which can provide good solutions for the metal processing industry, and is ready to better serve the metal processing industry.

Kuka China Product Manager Fu Yongxiang delivered the acceptance speech

Driven by the demand for new energy vehicles, lithium batteries, semiconductors and emerging markets, China’s welding market is growing rapidly. For customers in the manufacturing sector at the heart of the automotive and metalworking industries, it is important to automate complex welding tasks effectively and to carry them out perfectly, achieving welding with a high degree of system stability.

Today, not only advanced welding, but also simple welding applications require the participation of highly specialized robots, and the new generation of Kuka Edition series has been born.

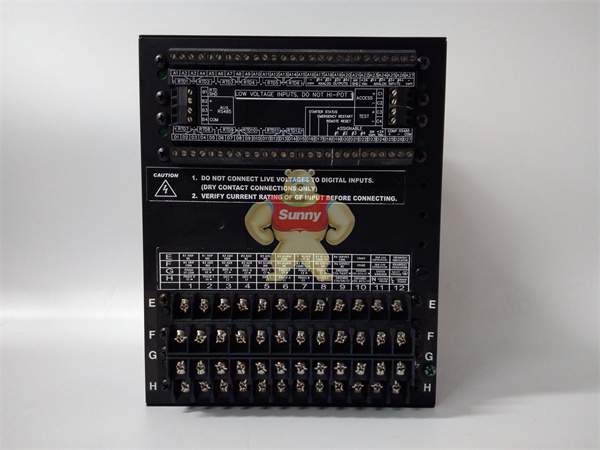

SR469-P5-HI-A20-E

SR469-P5-HI-A20-E

SR469-P5-HI-A20-E

The KR CYBERTECH nano ARC HW Edition series is a 6-axis robot product launched by Kuka in 2022. The large diameter hollow arm design brings better working condition accessibility, greatly reduces the collision risk of the pipeline package, ensures the stability of the arc welding process, and greatly reduces the maintenance cost. The rigid design, the robot shows good positioning ability in the arc welding process, and the repeated positioning accuracy can reach ±0.04mm. The rated load is 6kg, and the maximum load can reach 9kg. It provides two arm spans of 1440mm and 2010mm for choice, and supports two installation modes of formal installation and flip installation to meet the needs of different scenarios. In addition to hardware design and performance, Kuka is equipped with a variety of software packages for the arc welding process, including: arc tracking, starting point locating, multi-layer multi-channel, laser tracking, laser locating, adaptive functions, and can match most of the common market welding machines, including EtherCAT, Profinet, Ethernet/IP and other communication protocols.

Kuka KR CYBERTECH nano ARC HW Edition arc welding robot

Questioning ourselves and reinventing ourselves is what Kuka is all about. From the launch of the KR 6 R1440-2 arc HW in 2022 to the KR 6 R2010-2 arc HW E and this year’s KR 20 R1820-2 E, Kuka China continues to penetrate into price-sensitive market segments to provide low-cost options for smes to automate their transformation. At present, the application range of Edition series robots has covered the handling, grinding, assembly, loading and unloading packaging, palletizing, arc welding and other applications, flexible, efficient, reliable and durable.

According to the latest World Robot Statistical Yearbook published by the International Federation of Robotics (IFR), the robot density in China’s manufacturing industry has reached 322 units per 10,000 workers, ranking fifth in the world, and this number is still growing. In line with this trend, Kuka China has set up two research and development centers in Shunde and Shanghai, and has laid out production bases in Shunde, Kunshan and Shanghai. Among them, the Midea Kuka Intelligent Manufacturing Science Park located in Shunde covers an area of 288,600 square meters, which is currently the largest robot body production base in South China. By the end of April 2023, the park has produced and delivered more than 57,000 industrial robots to customers, with a cumulative output value of nearly 10 billion yuan. With the full operation of the park, the Shunde base plans to have a robot production capacity of 80,000 to 100,000 units per year in the future, comprehensively promoting the localization of robot supply. Kuka’s East China manufacturing base in Kunshan was also upgraded and put into use in April 2023.

In the future, Kuka China will continue to expand the possibilities of robot application, while leveraging the huge advantages of supply chain localization to help the comprehensive high-quality development of China’s manufacturing industry.

1 Year Warranty

1 Year Warranty