ForwardX Robotics (hereinafter referred to as “Smart Technology”), the world’s largest visual AMR enterprise and the first “order-to-person” solution provider in Asia, announced the completion of the C+ round of financing, the financing amount of 200 million yuan, and the total cumulative financing of the C round has exceeded 650 million yuan, ranking among the best in the track. This round of financing is jointly invested by Anhui State Holding Investment, Hefei High Investment and Hefei Investment Capital, and the funds raised will be mainly used for new product research and development, overseas market expansion, commercial delivery and supply chain deployment.

Smart Technology is the pioneer and leader of the fourth generation of mobile robots (visual AMR), the only full-range, end-to-end, visual AMR solution provider in the world, focusing on the development of visual autonomous mobile robots and intelligent robot cluster scheduling system, providing end-to-end automation solutions for the logistics industry and manufacturing industry. At present, the visual AMR solutions provided by Lingmo Technology have covered four continents of the world, including Asia, America, Australia and Europe, deploying nearly 3,000 visual AMR units, more than 150 commercial projects have been successfully delivered, and the re-purchase rate has reached 100%. Since its establishment 7 years ago, Lingdong Technology has accumulated financing amount of nearly 1 billion yuan, and has become the enterprise with the largest shipment volume, the most industry coverage and the most extensive landing scene in the field of three generations and above mobile robots, occupying the “first” position in the scale of visual AMR enterprises with absolute strength.

At the same time, after years of development, Smart technology Vision AMR has realized the rapid landing of a variety of complex scenes across different industries such as logistics and automobile manufacturing, creating the strongest solution in the subdivision field, and achieving rapid growth of the company’s revenue.

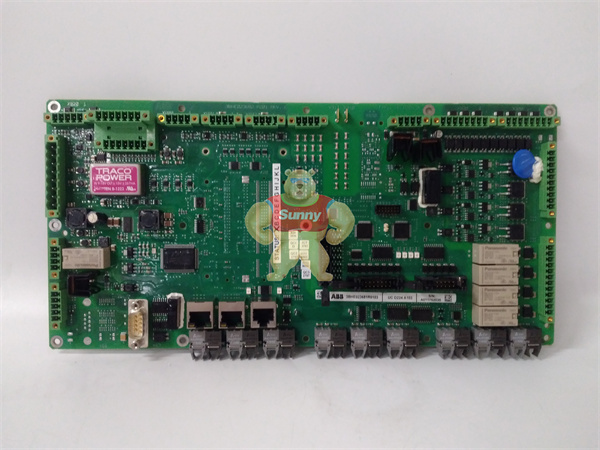

UCD224A103 3BHE023681R0103

UCD224A103 3BHE023681R0103

Warehouse Automation: Asia’s largest order-to-person solution provider

Mobile robots have been advancing all the way since 2021, so that capital is full of unlimited expectations for this emerging blue ocean market. Relevant data show that industrial AMR sales in the Chinese market in 2021 have broken 10,000 units, an increase of nearly 100%.

Qi Ou, founder and CEO of Lingmo Technology, said, “Behind the high growth of the mobile robot track, it also conveys a clear signal that the storage automation market is becoming more mature from the side.” Chinese mobile robot enterprises to go global, is no longer a choice, but a must.”

For the logistics industry, Lingzhi Technology in the country’s first “order to people” flexible picking solution, through the “one person to pick more cars, one car to many people, people and cars together” greatly improve the picking efficiency, save picking personnel. “Order-to-person” is currently the most sought after warehousing logistics solution worldwide, and it is also the only solution that delivers true commitment to customer ROI and no sunk costs. “Order to person” has high flexibility, can adapt to the industry ToB, ToC business model selection scenario, especially for small, medium, small and medium-sized mixed, and even medium and large goods, can greatly reduce the labor intensity of personnel.

At the same time, “order to people” can achieve “traceless deployment, zero cost migration, adaptive business, one minute to get started”, with half the investment to bring twice the efficiency of selection, to achieve double improvement of human efficiency and ping efficiency. Up to now, Lingda Technology’s “order-to-person” flexible picking solution has deployed nearly 3,000 AMR units worldwide, becoming the first “order-to-person” solution provider in Asia in terms of shipments and market share. Taking a domestic leading logistics enterprise as an example, Lingdong Technology’s “order-to-person” flexible picking solution has been quickly launched in its 10 warehouses within 100 days, and the picking efficiency has been increased by 50%-200%.

1 Year Warranty

1 Year Warranty